Overview

PBL Pharma division offers a line composed of three machines: washing machine, depyrogenization tunnel, filling and closing machine; completely integrated with each other to obtain maximum productivity. The machine has a compact and user-friendly interface. A careful design of the line and careful research into materials guarantee the best performance and best cleaning even with aggressive products. The machine can be positioned in ISO 7 and ISO 5 area using validated process that are constantly monitored and controlled.

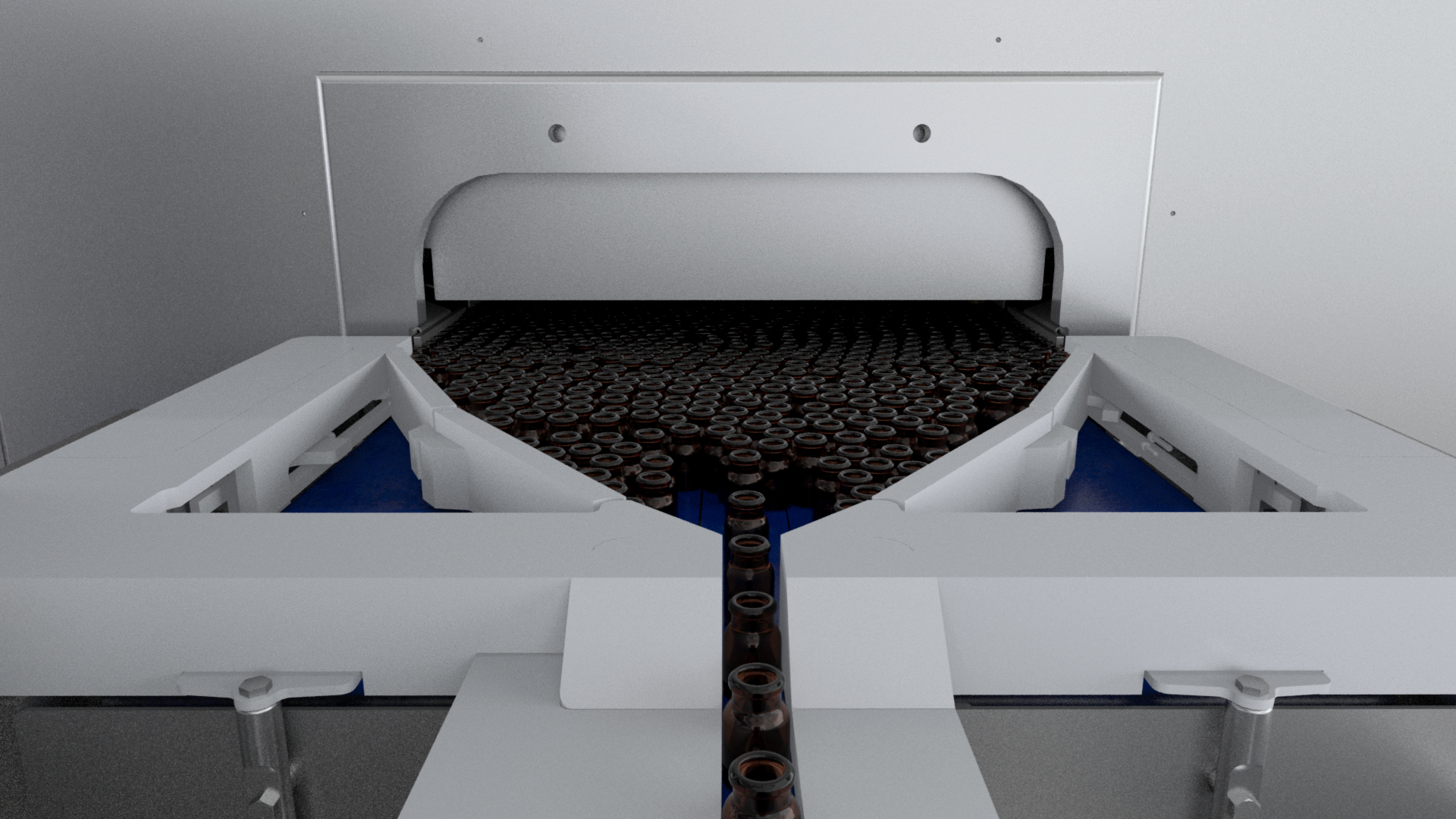

Hydro

Main features

• Loading system by B-Flow table

• Washing and drying stations

• Various monitoring functions

• Customized transport system

More features

⦁ Quick and easy format change tools free

Machine Output

50 to 400 PpM

Compatible containers

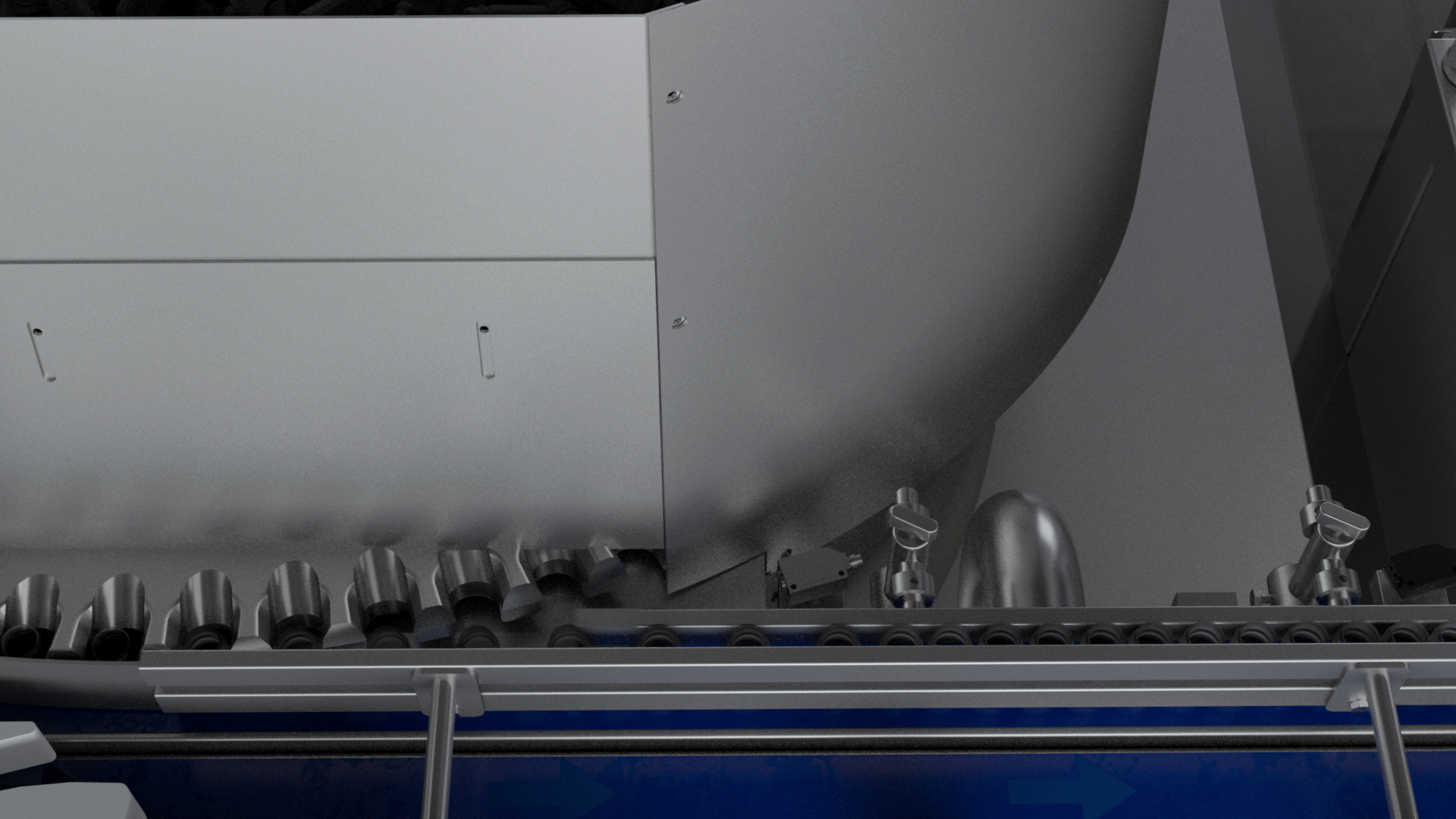

DTM

Main features

• Depyrogenation tunnel

• Inlet chamber

• Hot chamber

• Cooling chamber

More features

⦁ 6 Log reduction

Machine Output

50 to 400 PpM

Compatible containers

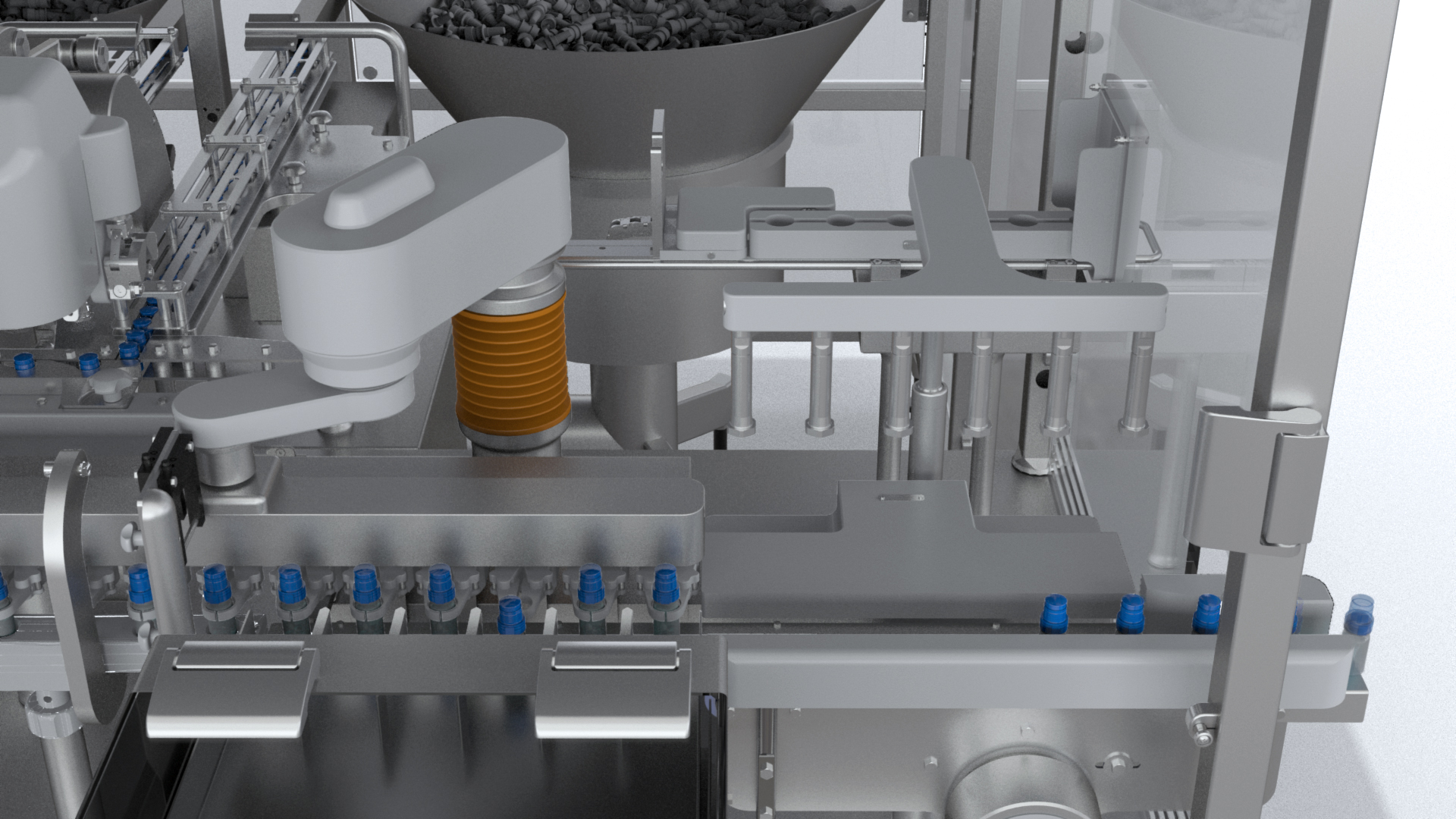

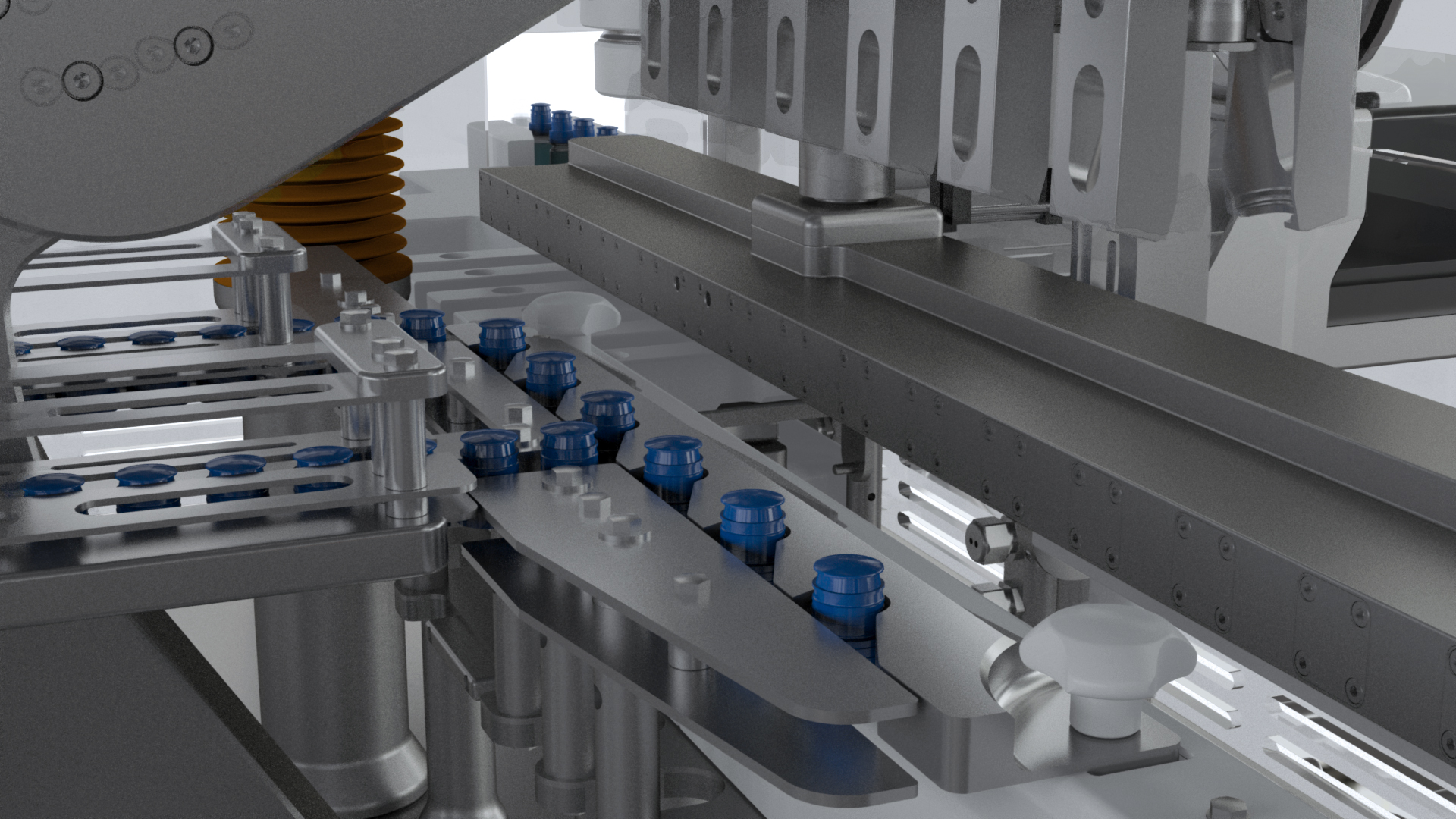

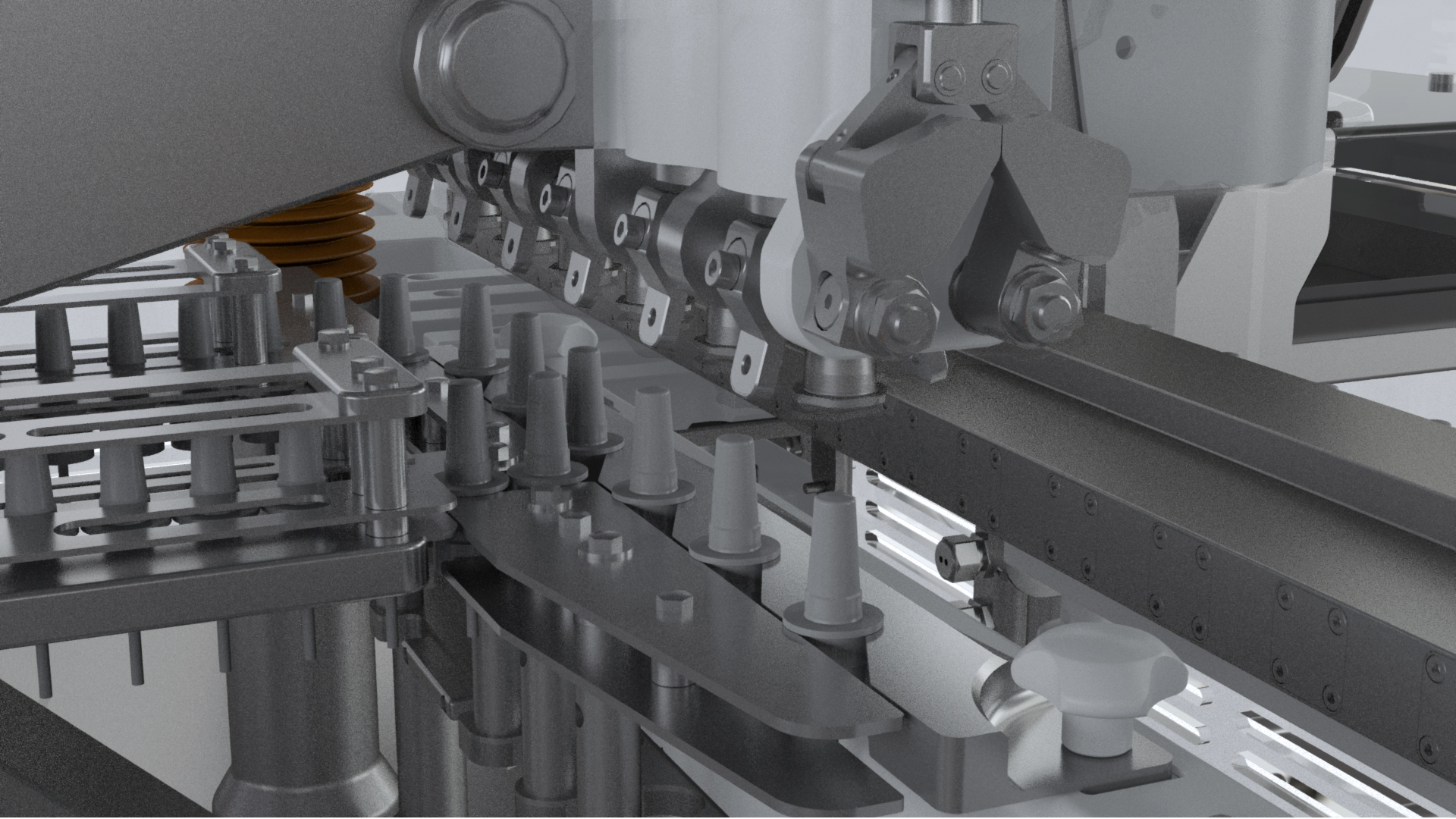

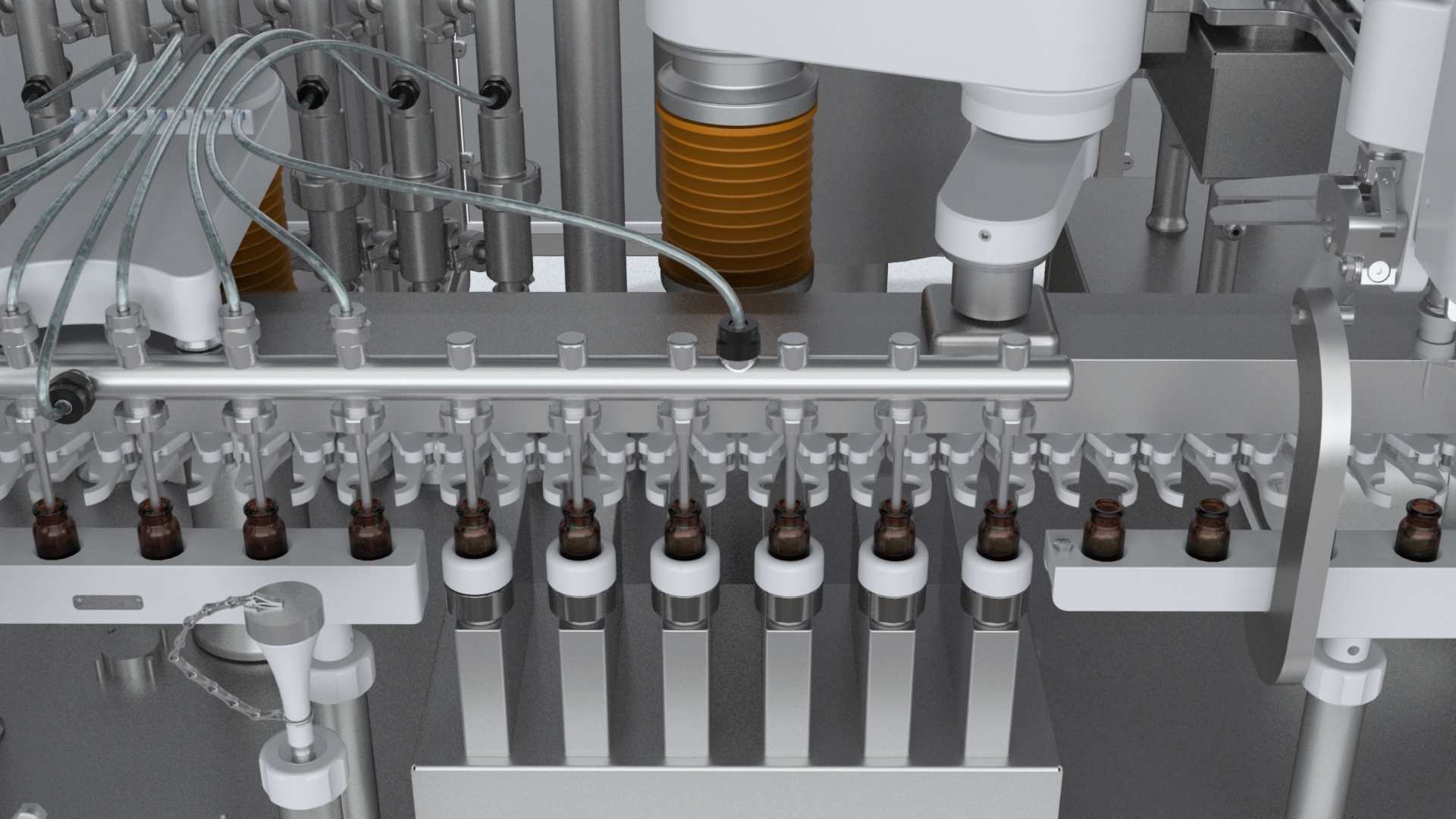

NI-FILL

Main features

• Glass vials rotary table buffer

• Unscrambler for plastic bottles

• Internal air blowing/suction system for plastic bottles

• Filling system with peristaltic pump (disposable) or piston filler

More features

⦁ Syringes and Cartridge TUB and NEST preparation

⦁ Vials Trays

⦁ Container Nesting

⦁ Control of complete and conforming nest

⦁ Tyvek position and sealing

⦁ Sterile bag bagging

⦁ User-friendly and fast tool-free format change

⦁ Designed as a modular machine

Machine Output

50 to 400 PpM

Compatible containers

Contact us