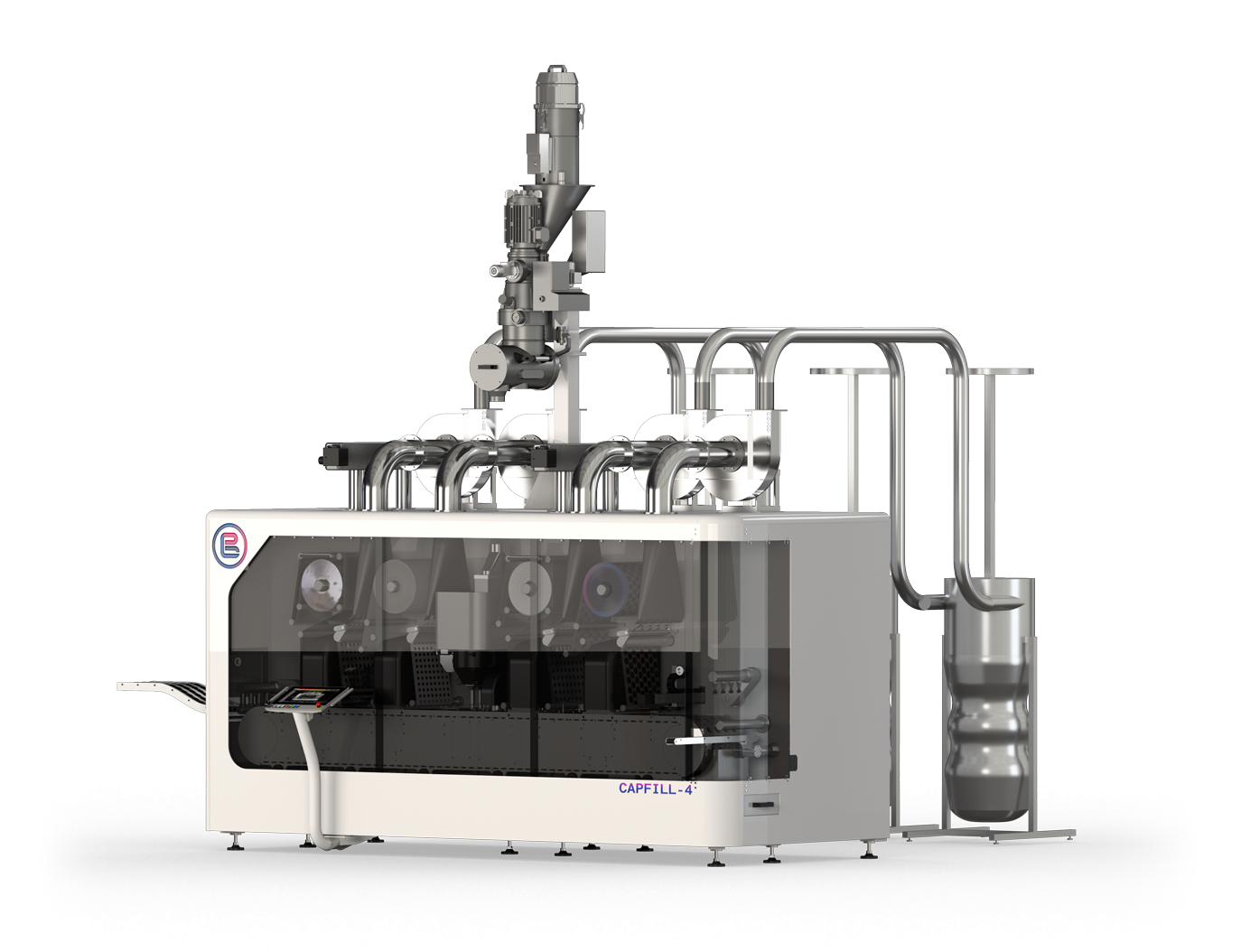

Overview

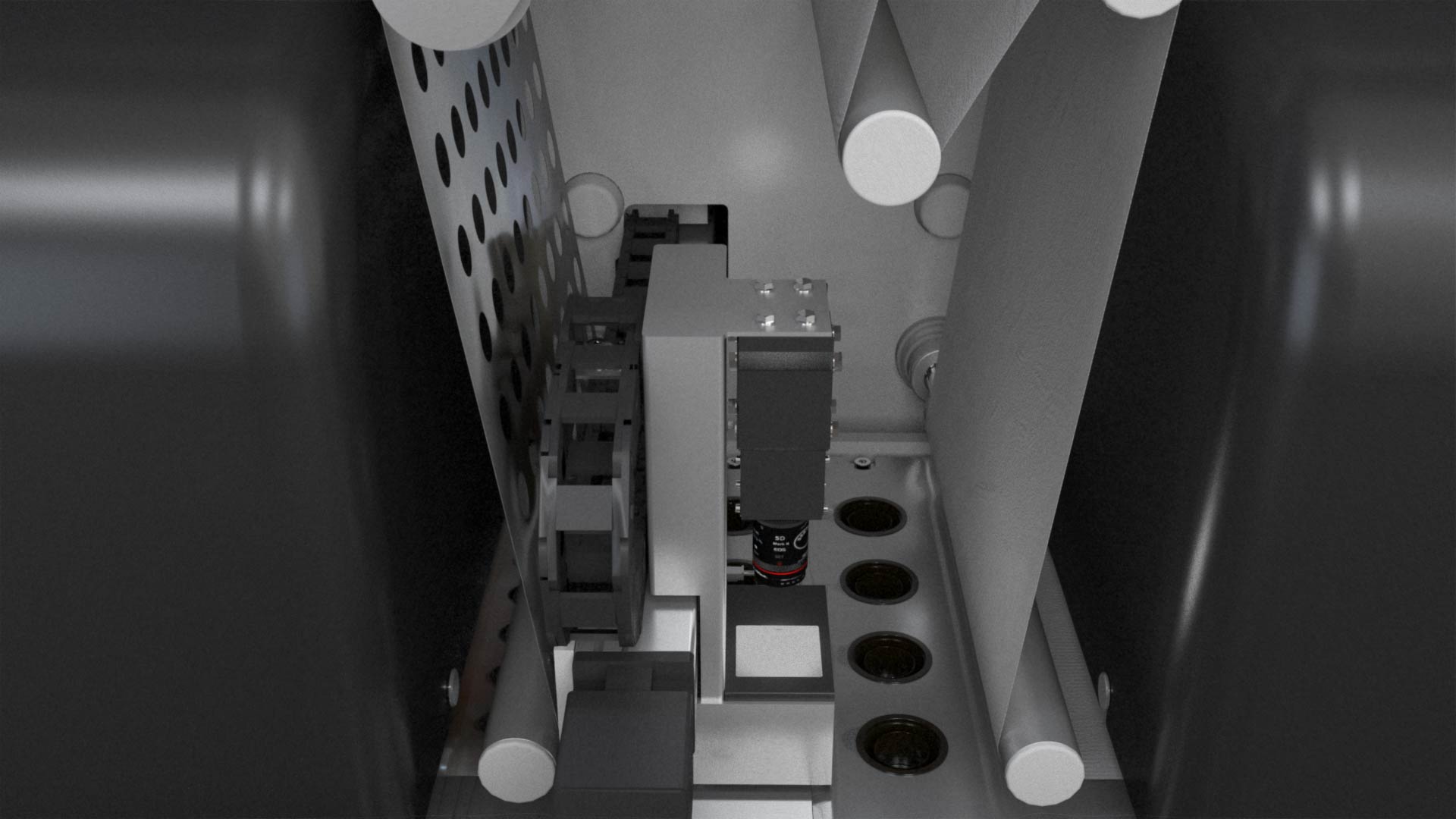

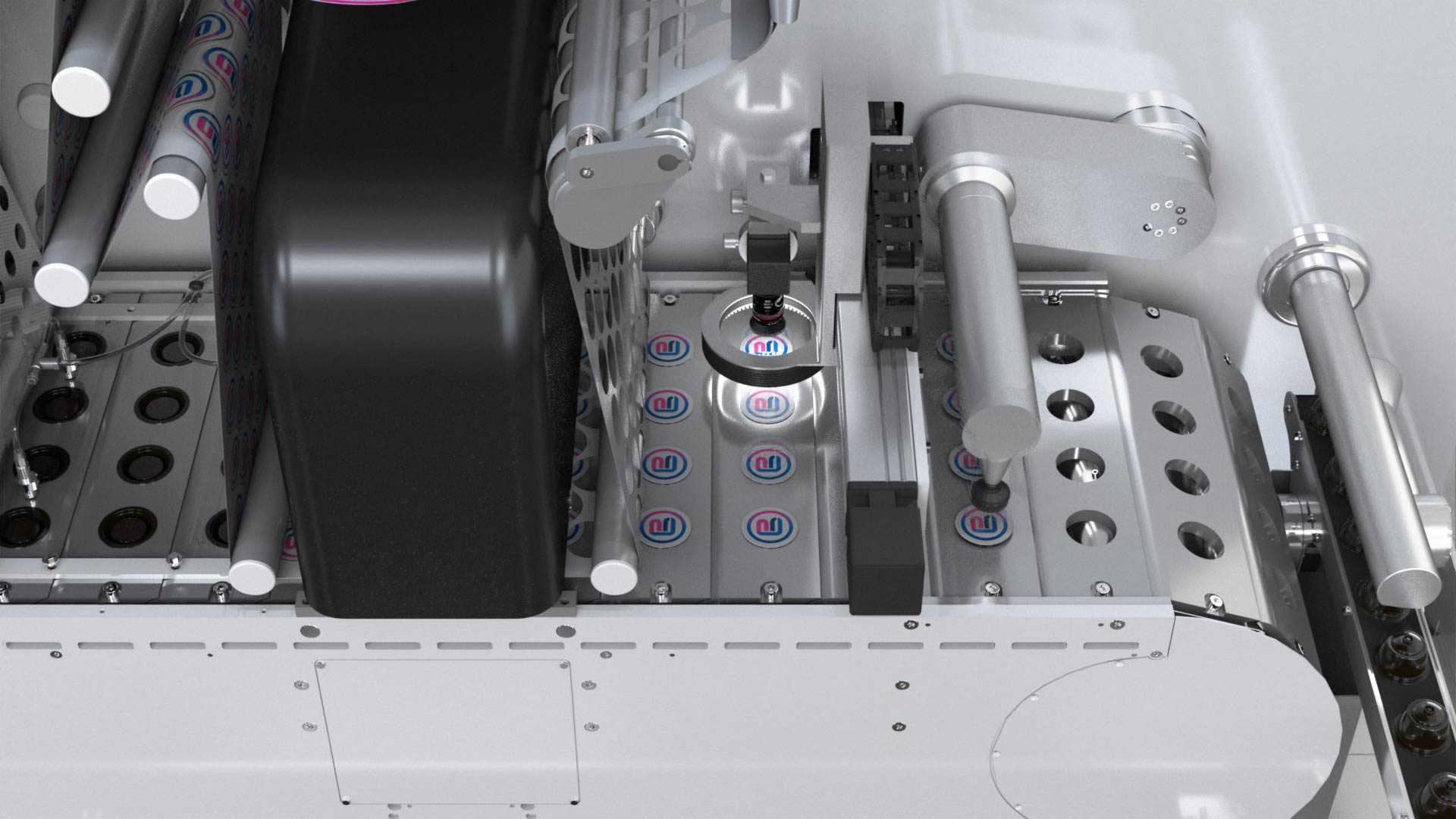

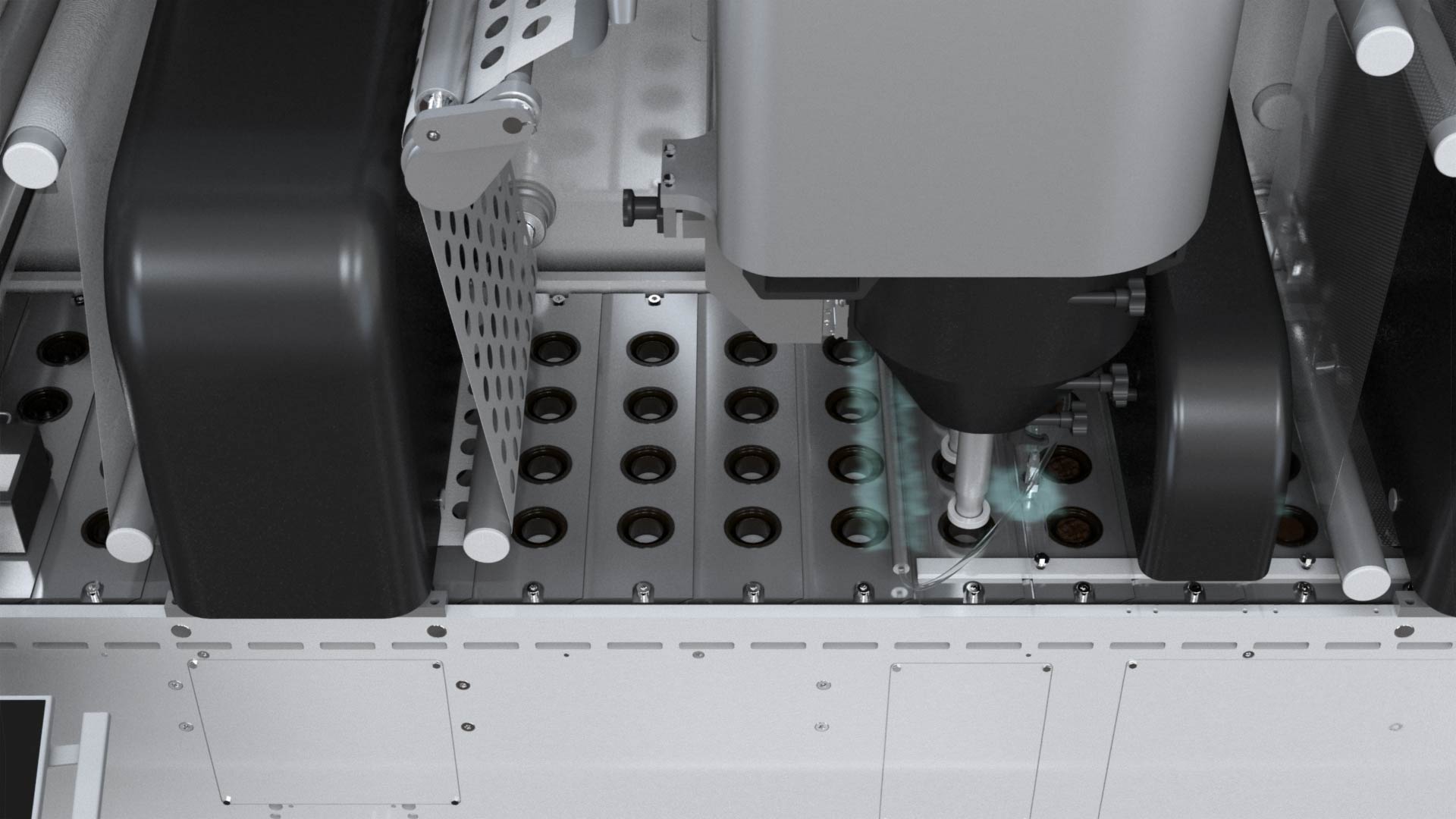

CAPFILL Series are automatic filling machines designed and built by PBL Consumer Division. PBL brings new concepts and solutions from the Pharma Division to the Consumer Division, this includes CVS (Compensated Vacuum System), IPC (100% In-Process Control) with retroactive feedback to the dosing system. Our dosing system offers high accuracy and efficiency. Our R&D department is continuously studying innovative solutions to respond to customers’ needs, such as a new Film Saving Device that reduces the waste of material in addition to an easy maintenance process.

Main features

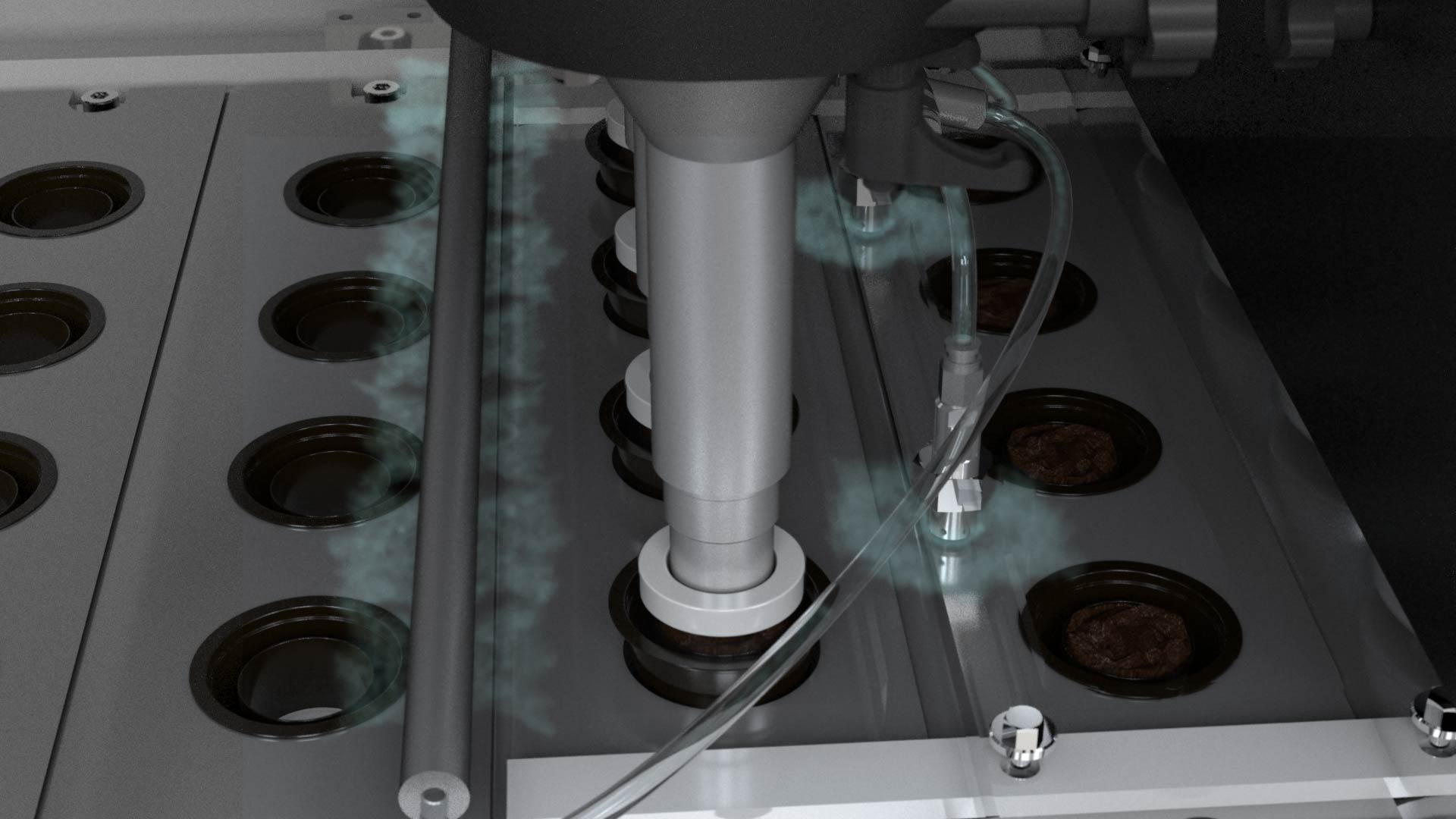

⦁ Dosing unit for powder, solubles and liquid

⦁ Product compacting and capsule rim cleaning unit

⦁ CVS (Compensated Vacuum System) with less than 55% of nitrogen consumption

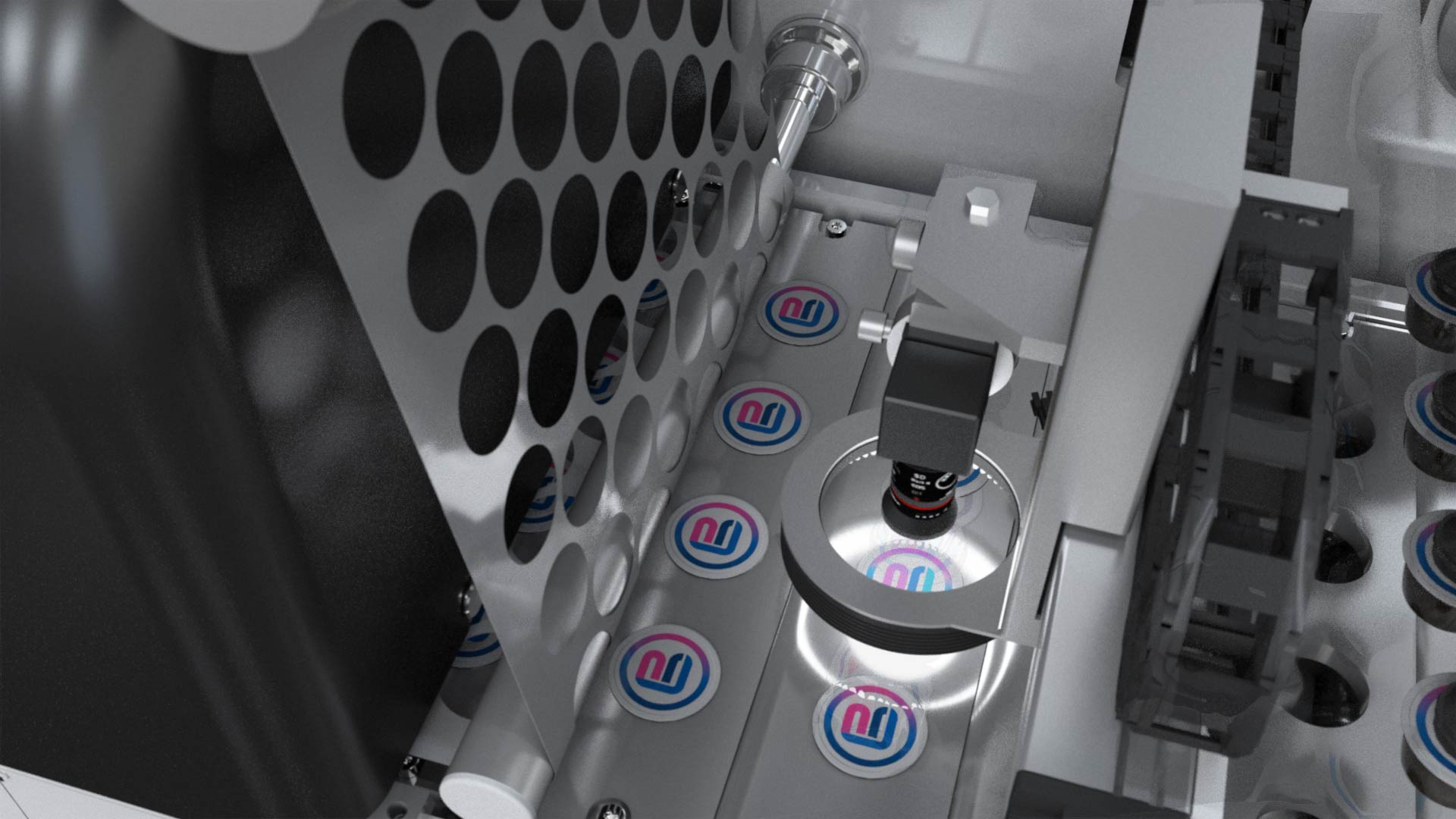

⦁ IPC (100% In-Process Control) with retroactive feedback to the dosing system

More features

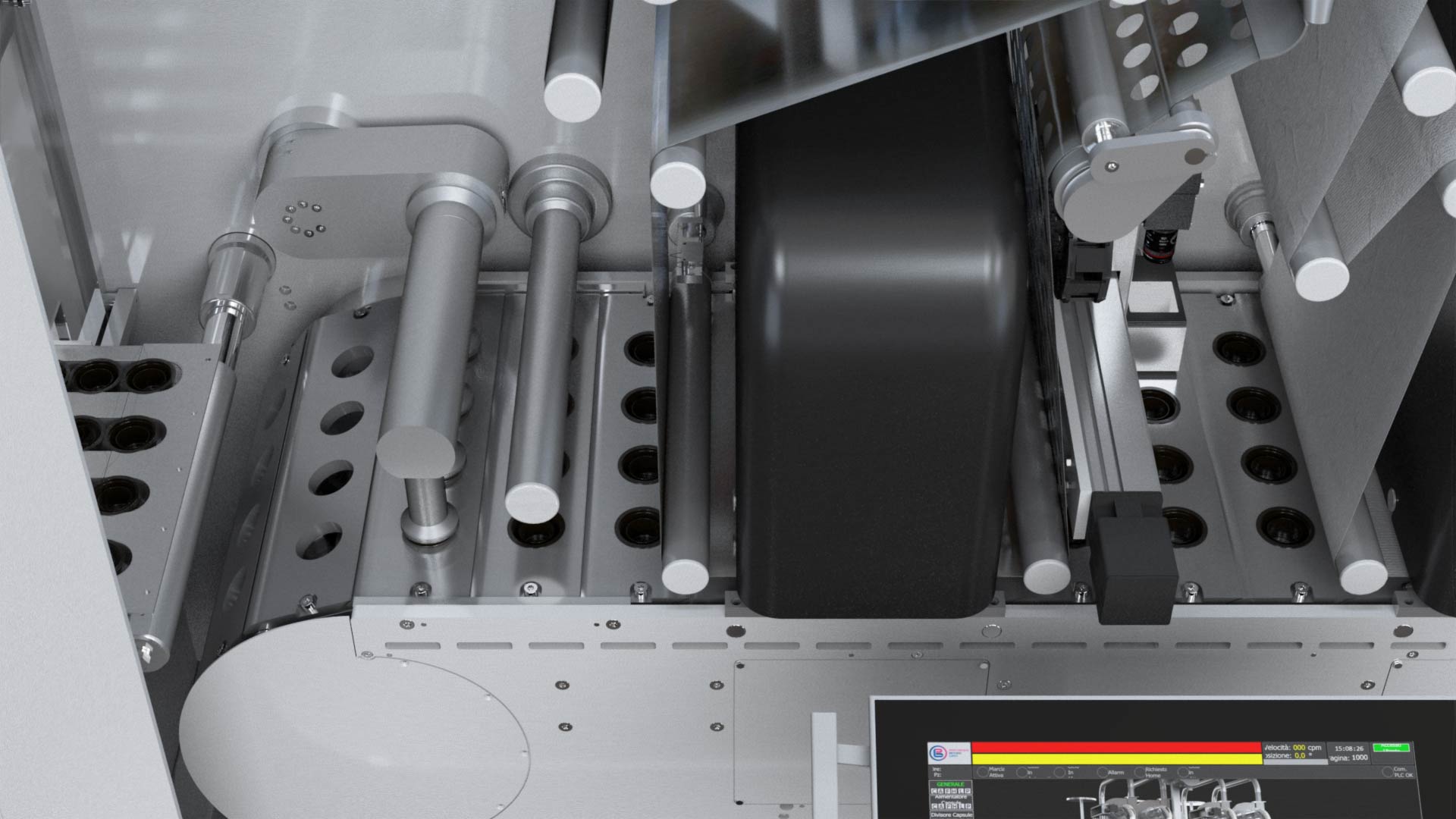

⦁ Customized transportation chain

⦁ Film saving device designed by PBL (up to 35% less waste)

⦁ Reliable thermal sealing process by induction or ultrasound

⦁ User-friendly and fast tool-free format change

⦁ Able to work with compostable and recyclable materials

⦁ Camera inspection system for intermediate and top lid

⦁ Designed as a modular machine, configurable with filling and sealing units

⦁ Capsule rejection device

Machine Output

Coffee

CAPFILL-2 120 CpM

CAPFILL-4 240 CpM

More options

CAPFILL-6 360 CpM

CAPFILL-8 480 CpM

CAPFILL-10 600 CpM

CAPFILL 2-2 120 CpM x 2 caps

Soluble/Infusions

CAPFILL-2 100 CpM

CAPFILL-4 220 CpM

More options

CAPFILL-6 330 CpM

CAPFILL-8 450 CpM

CAPFILL-10 550 CpM

CAPFILL 2-2 100 CpM x 2 caps

Compatible containers

Contact us