Overview

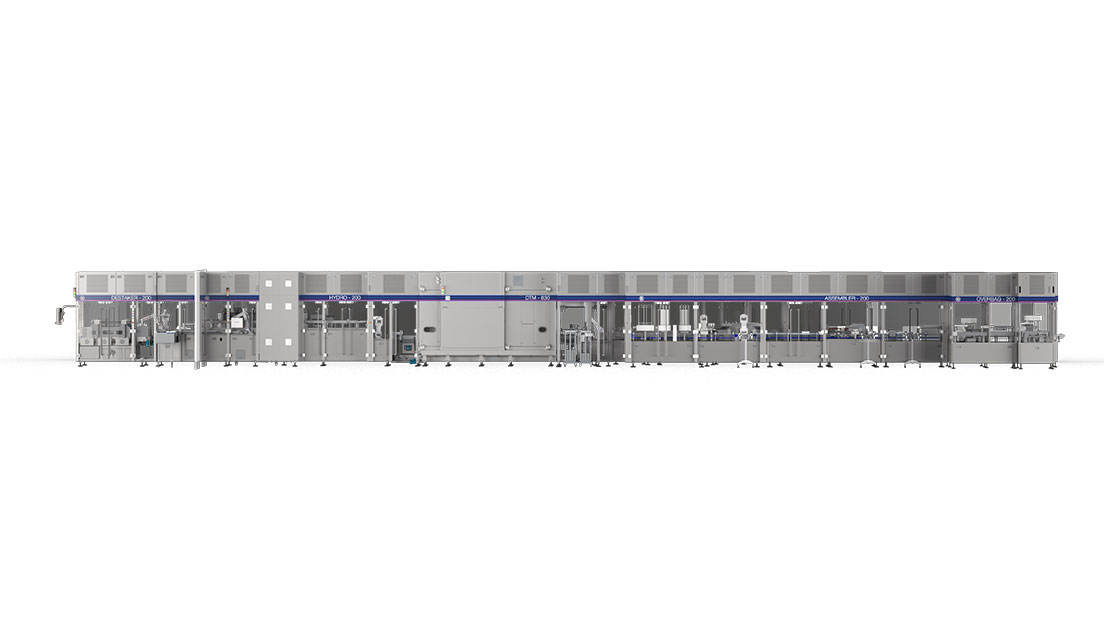

PBL RTF line offers complete robotic production lines for Ready-To-Fill (RTF) vials, syringes, and cartridges.

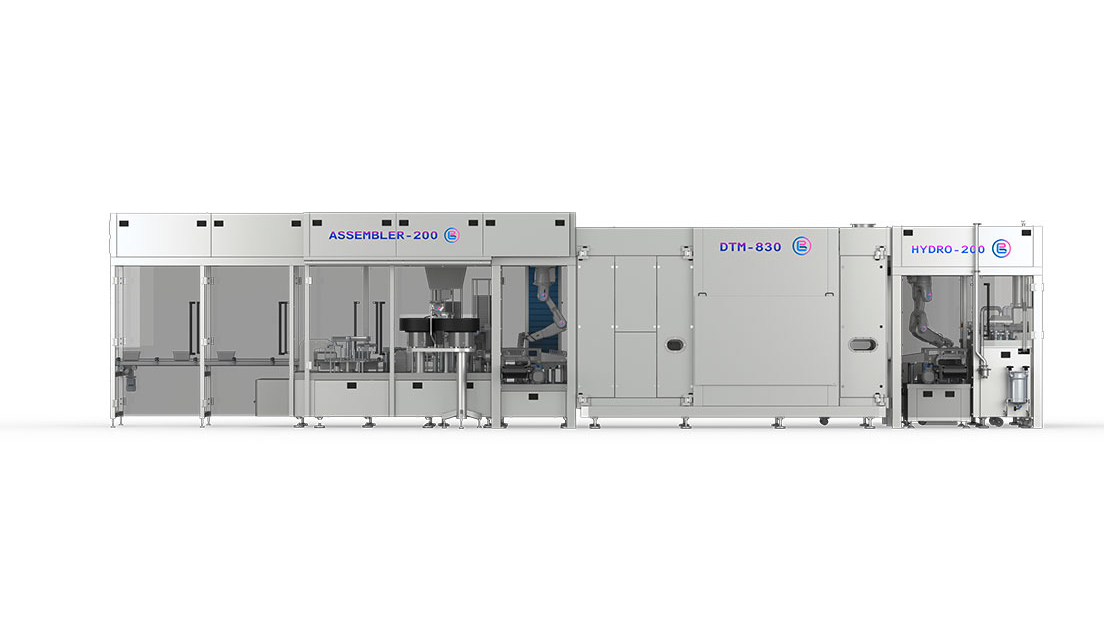

Our washing machines are designed for internal and external cleaning and drying of glass and plastic pharmaceutical containers.

Our depyrogenation tunnels are specially designed to be installed between a washing machine and an assembler or a final packaging system (depending on end-user requirements). These high output tunnels count on precise temperature control and heat distribution to ensure full sterilization of glass containers.

No glass-to-glass contact protects containers from cosmetic defects, particles, and contamination, thereby increasing production efficiency by way of fewer rejects.

Each production process uses state-of-the-art equipment.

RTF LINE (NEST/TRAYS)

RTF LINE (NEST)

RTF LINE (BLISTER)

Contact us