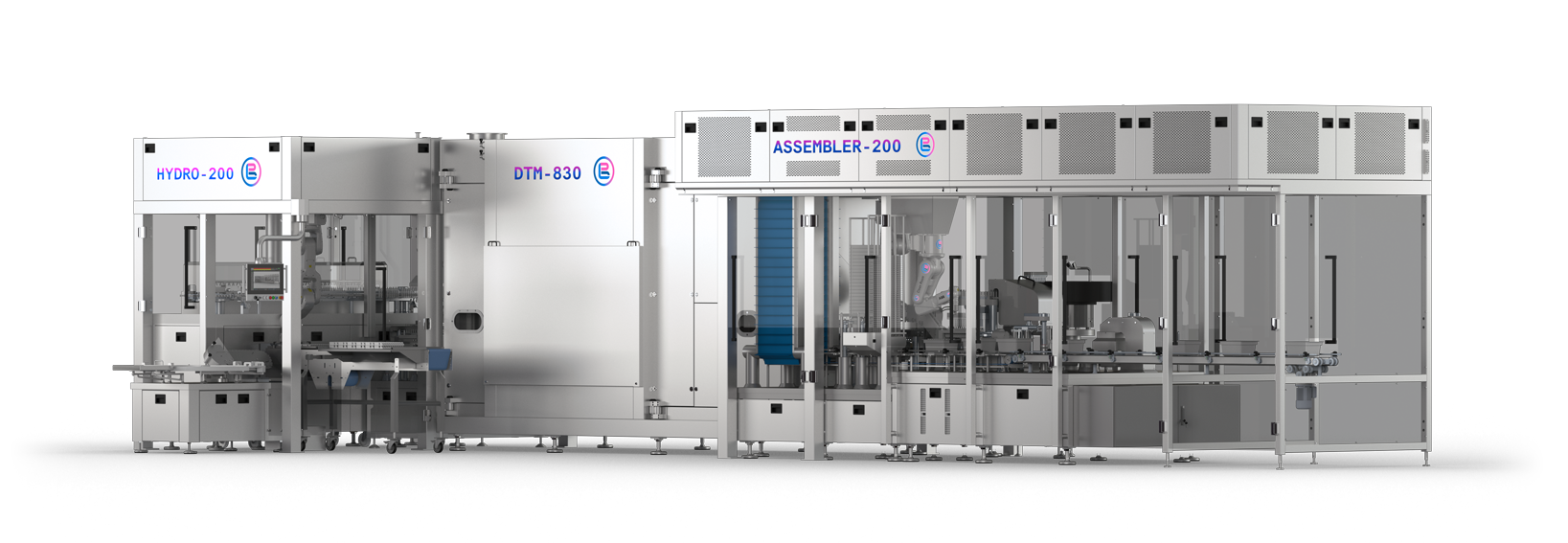

Overview

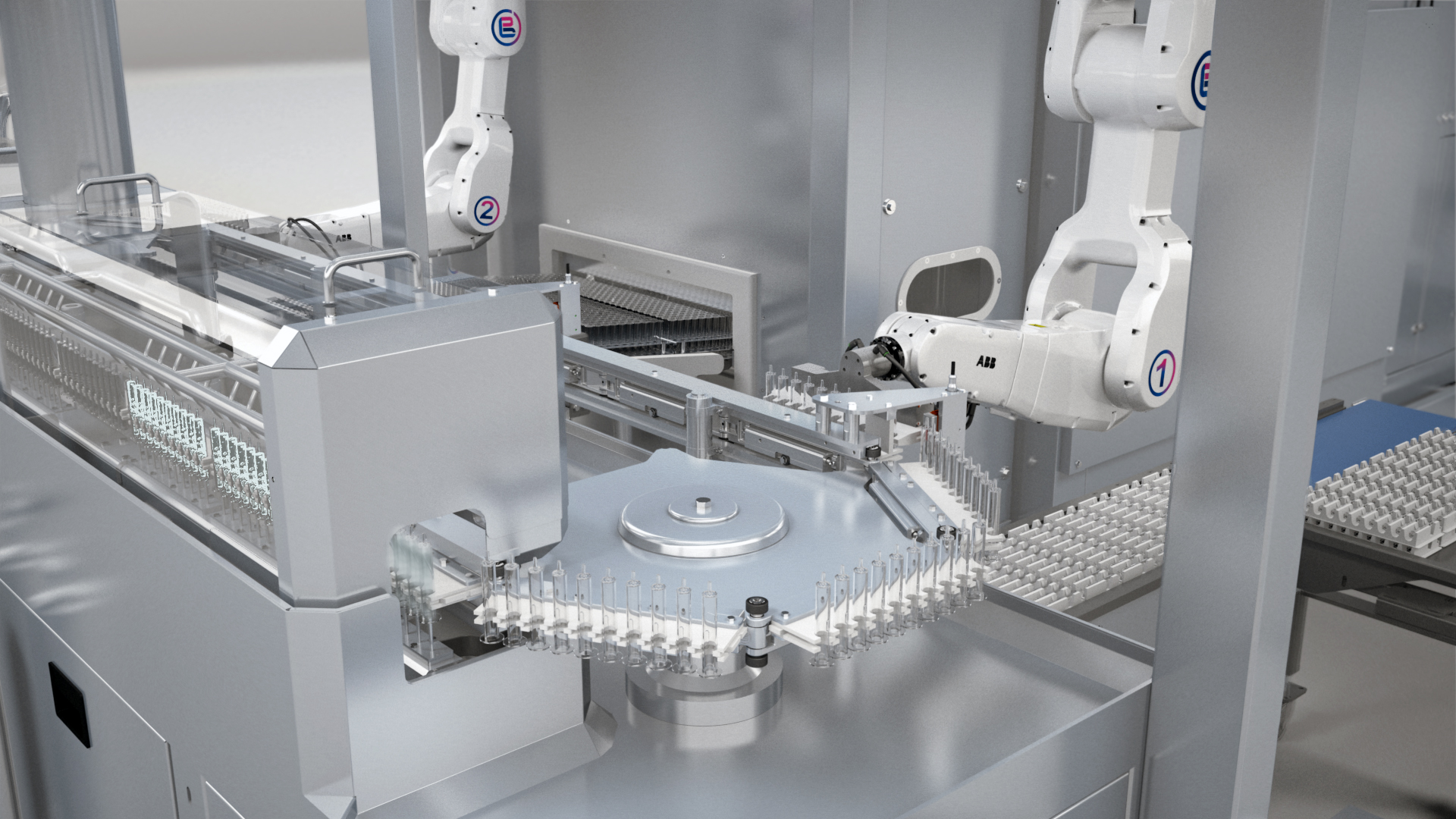

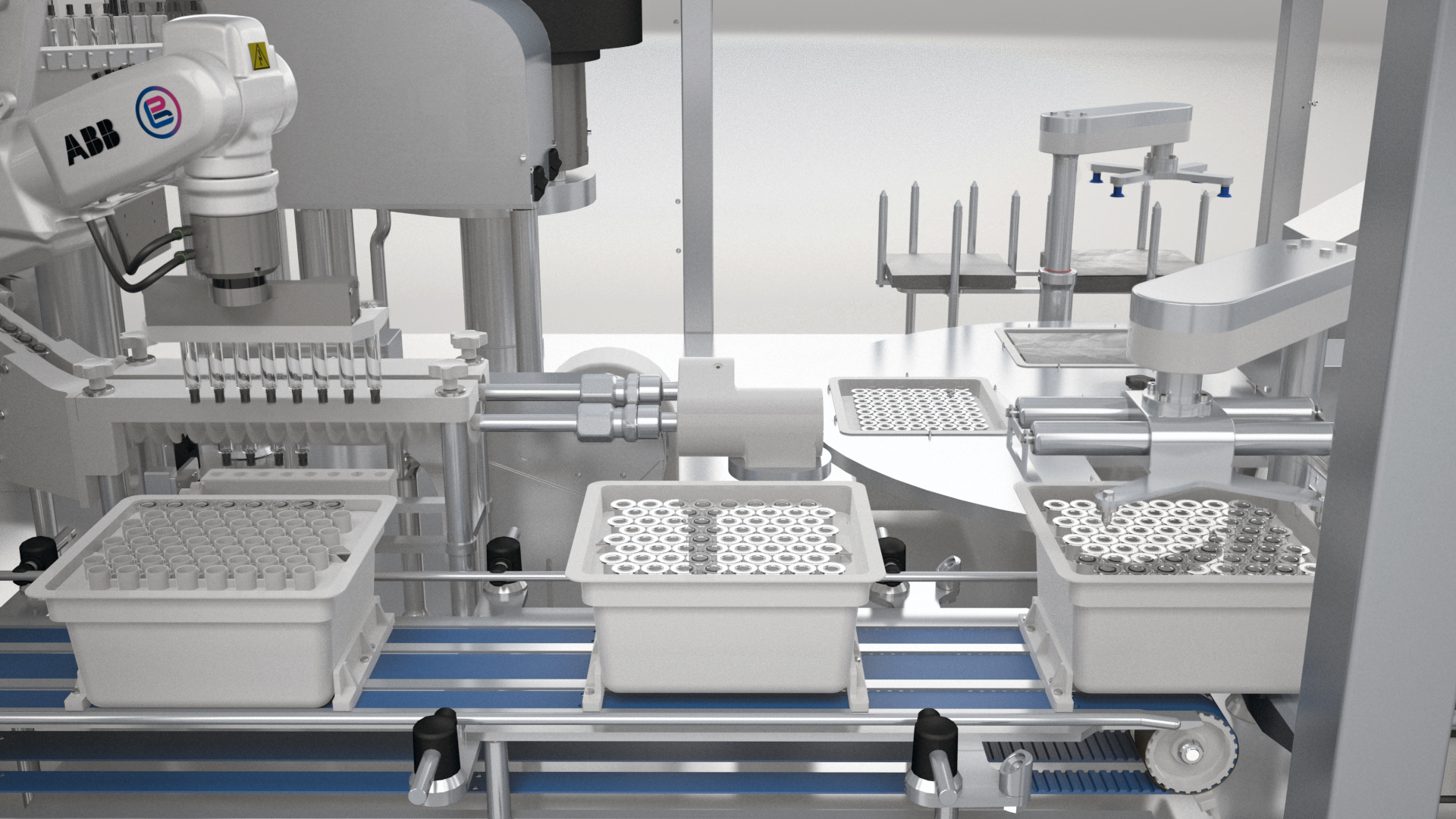

The line consists of three stations: washing machine, depyrogenation tunnel, and tray loading system, fully integrated for maximum productivity. No glass-to-glass contact protects containers from cosmetic defects, particles, and contamination, thereby increasing production efficiency by way of fewer rejects. Each production process uses state-of-the-art equipment. Certified ISO 7 and ISO 5 using validated processes that are constantly monitored and controlled.

Hydro

Main features

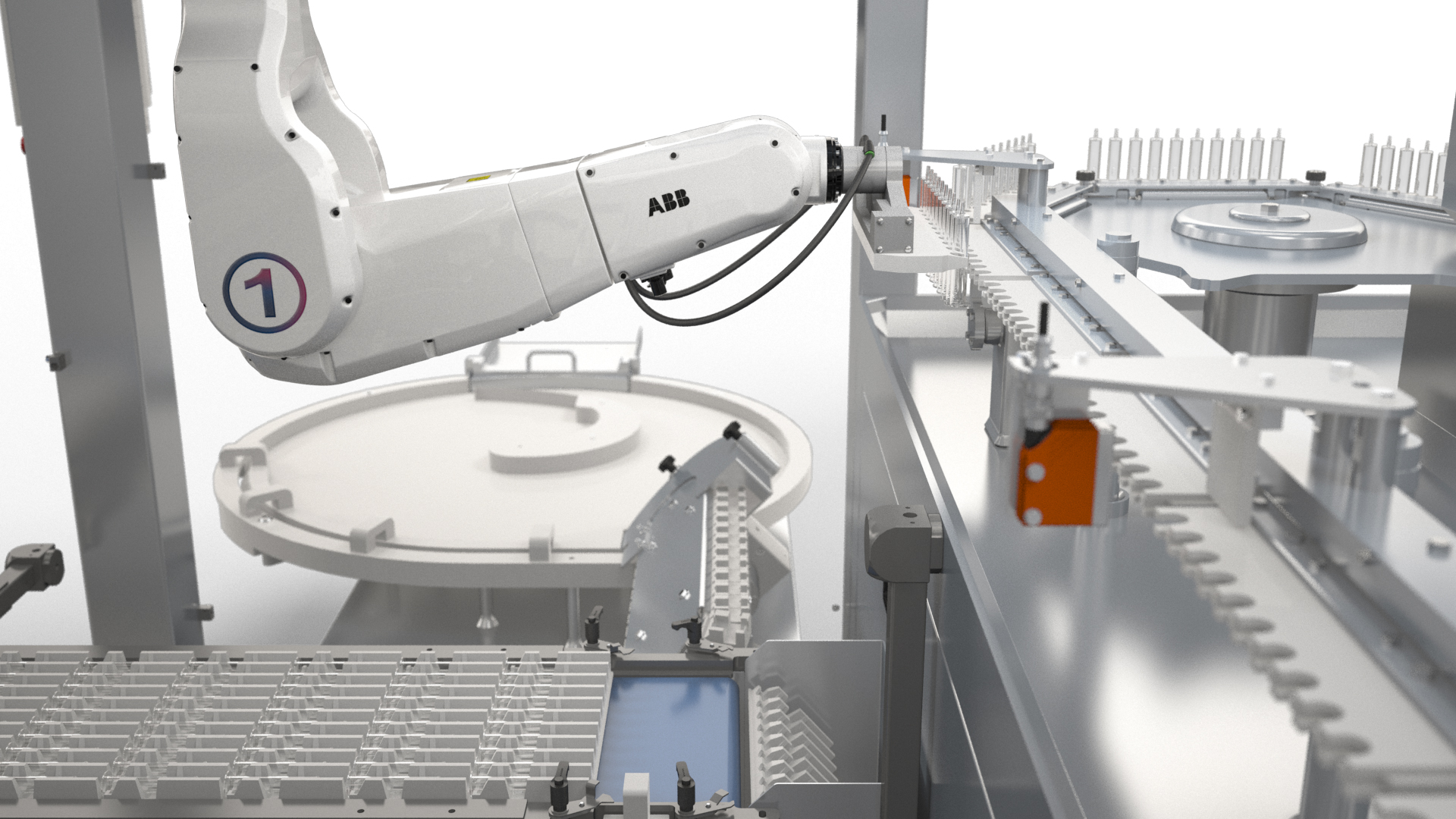

⦁ Robotic loading/unloading

⦁ Washing and drying stations

⦁ Compact wet chamber

⦁ Fast change format

More features

⦁ Siliconization cycle

⦁ Different monitoring functions

⦁ Customized transportation system

⦁ User-friendly and fast tool-free format change

⦁ Designed as a modular machine

Machine Output

100 to 400 BpM

Compatible containers

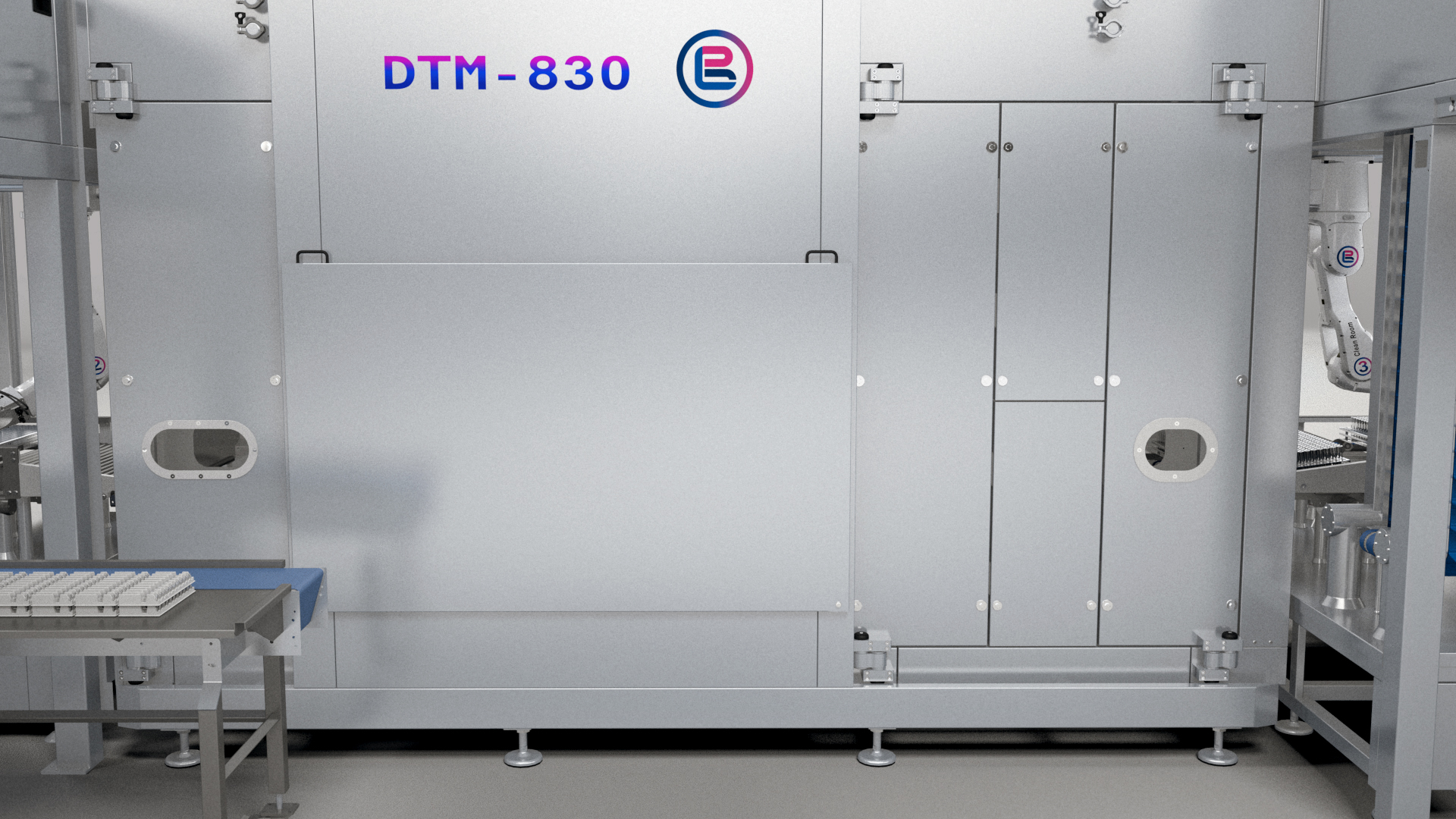

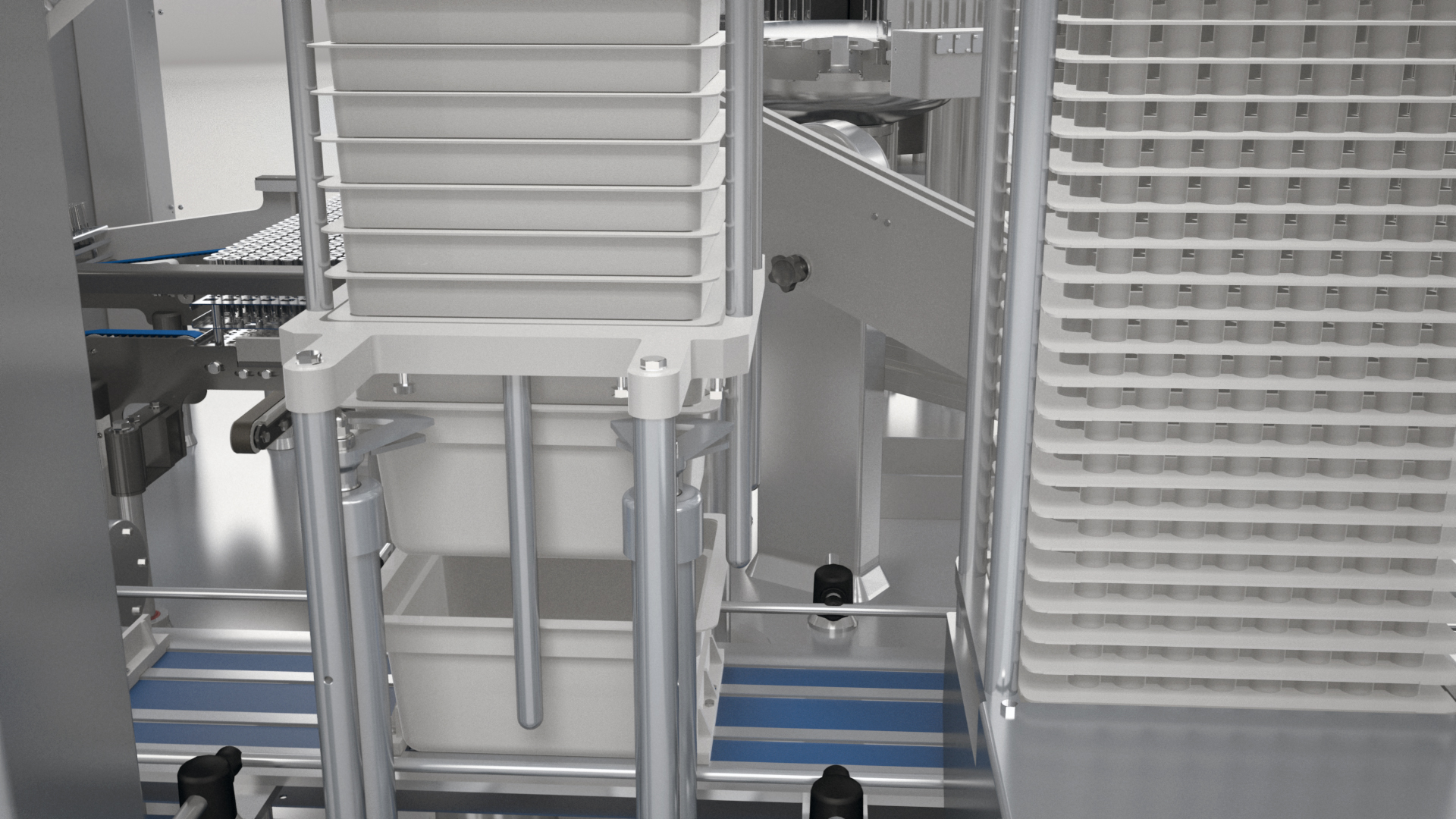

DTM

Main features

⦁ Depyrogenation Tunnel

⦁ Inlet chamber

⦁ Hot chamber

⦁ Cooling chamber

More features

⦁ 6 Log reduction

⦁ User-friendly and fast tool-free format change

⦁ Designed as a modular machine

Machine Output

100 to 400 BpM

Compatible containers

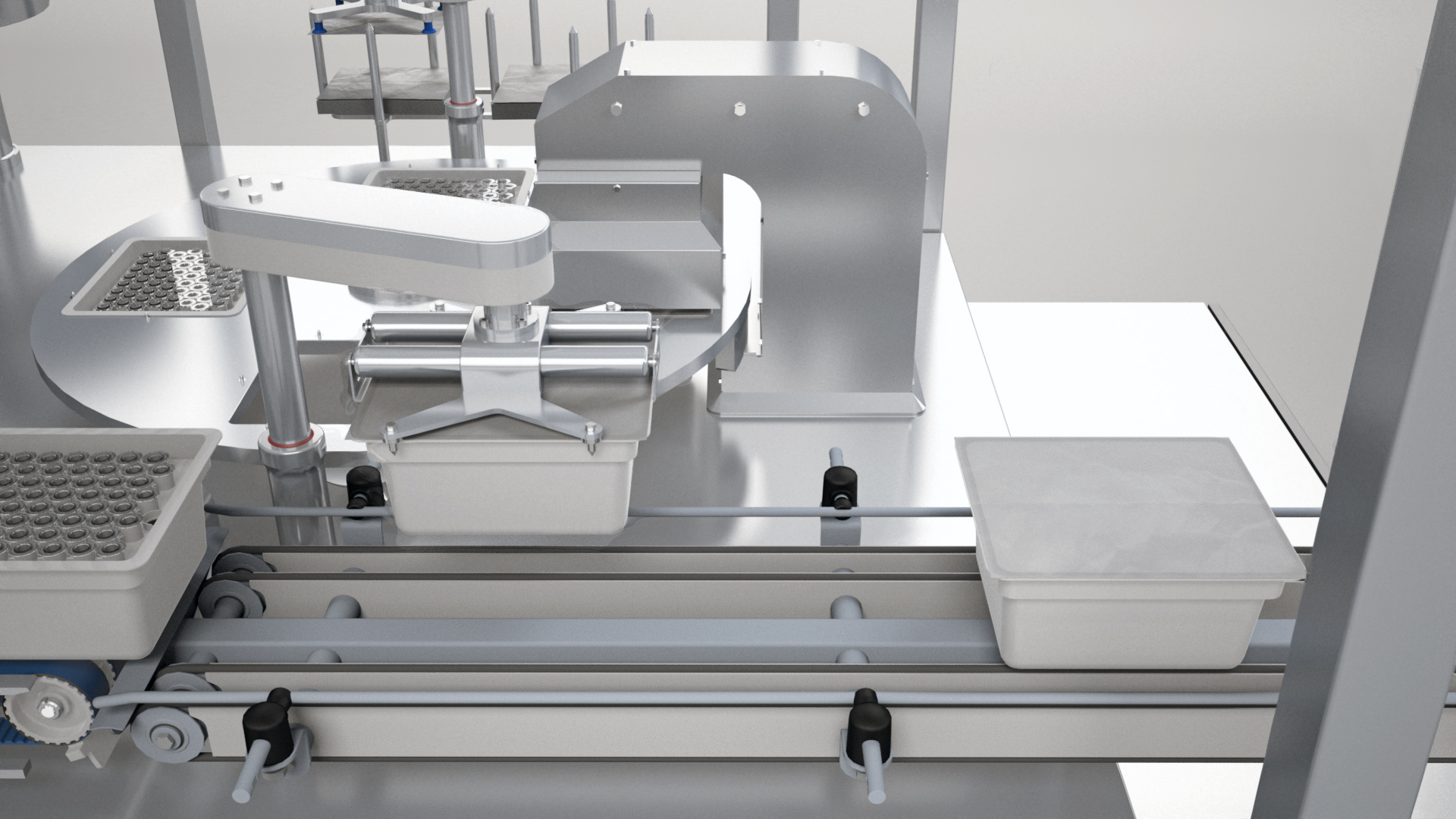

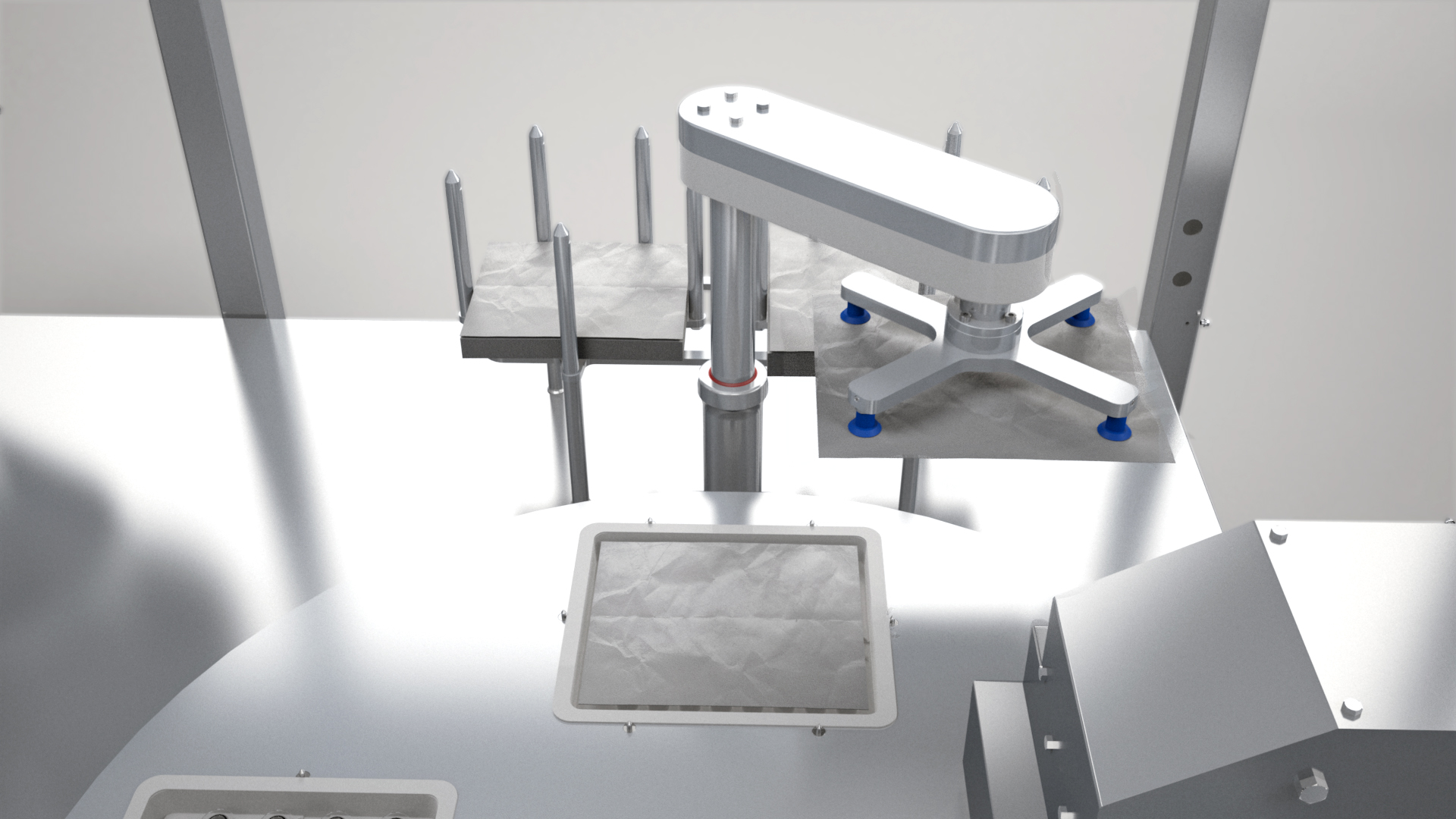

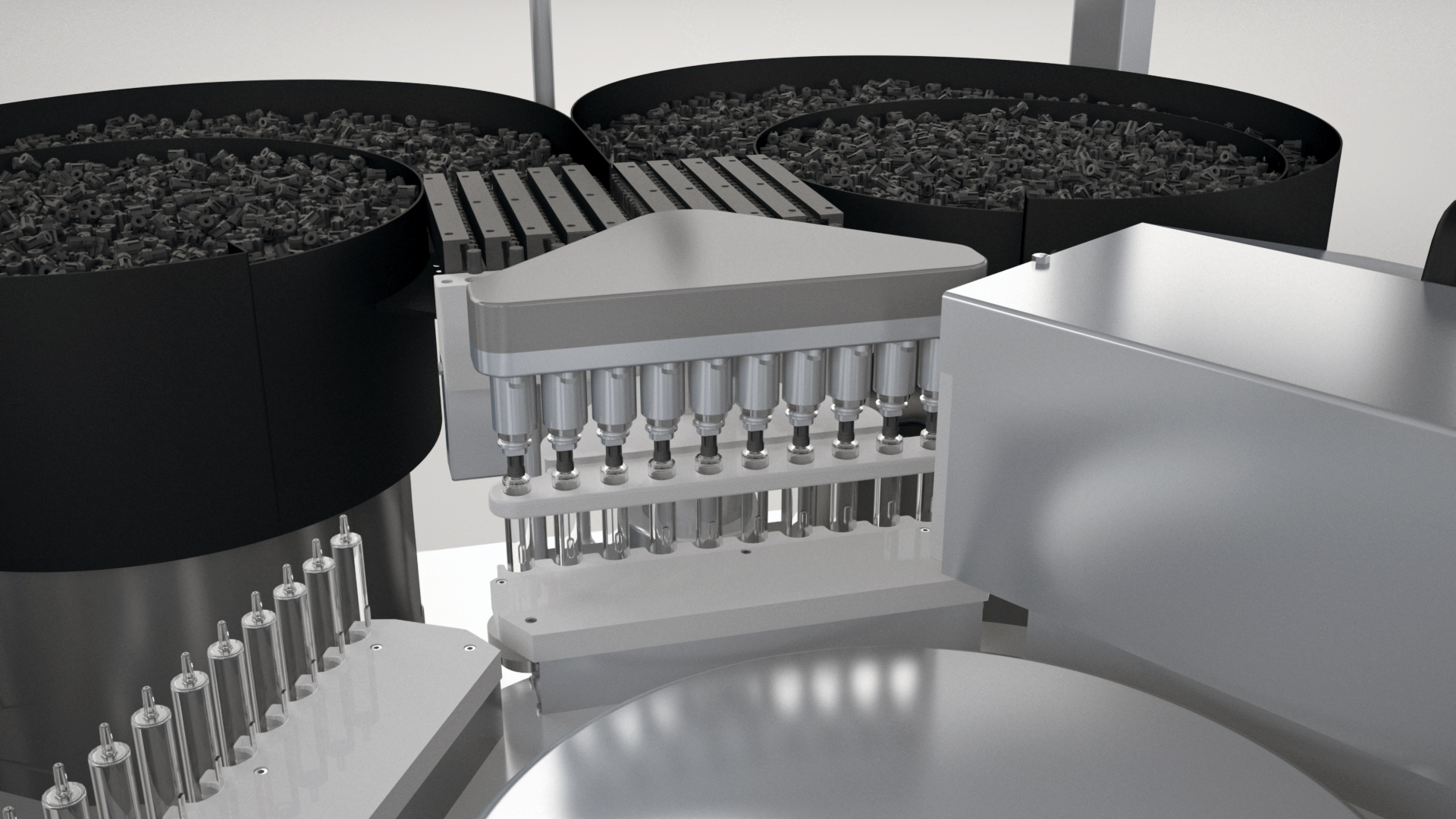

Assembler

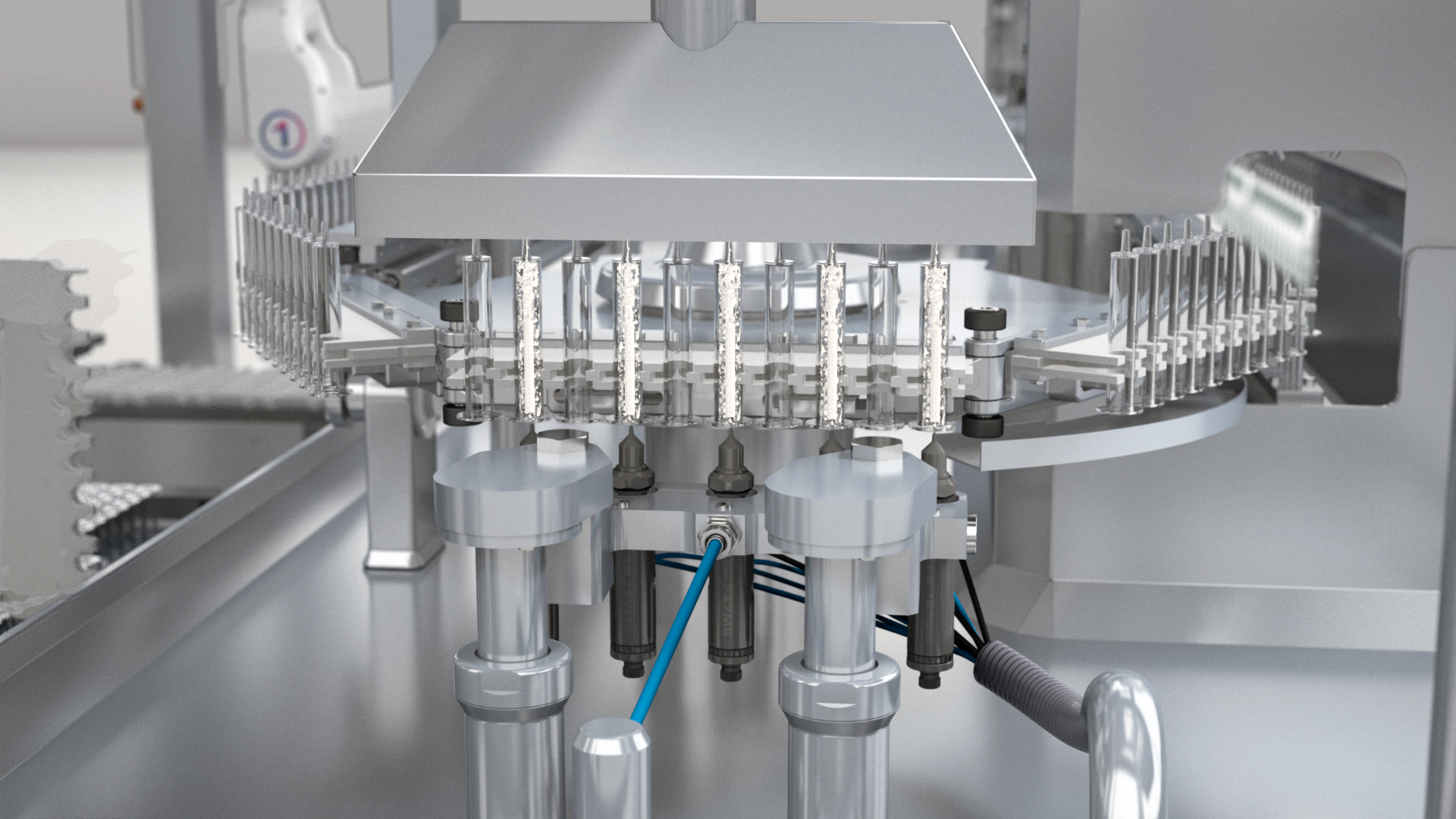

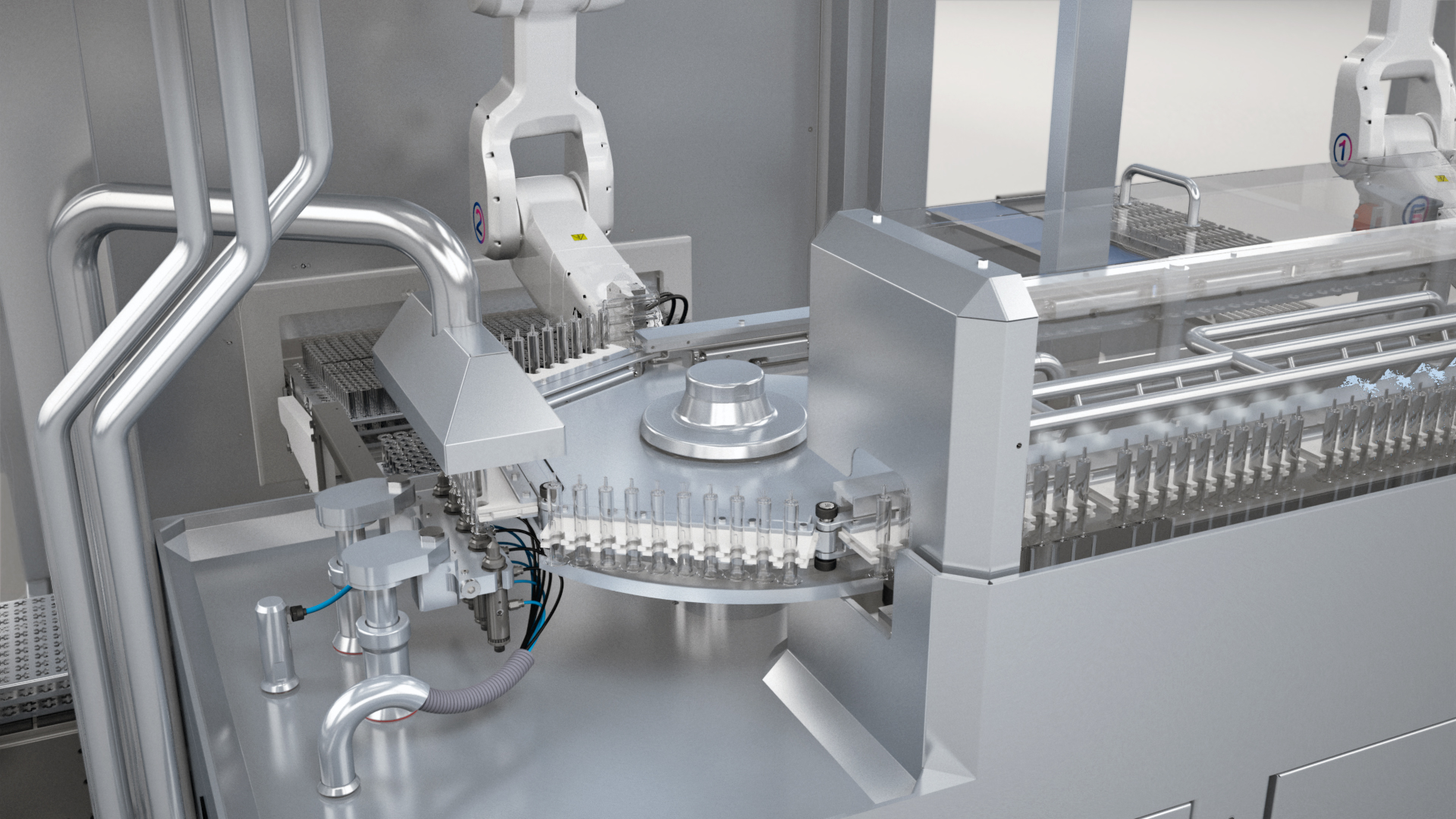

Main features

⦁ Capping/alu process

⦁ Siliconization process

⦁ Control of stopper/alu position

⦁ Control of correct silicon application

More features

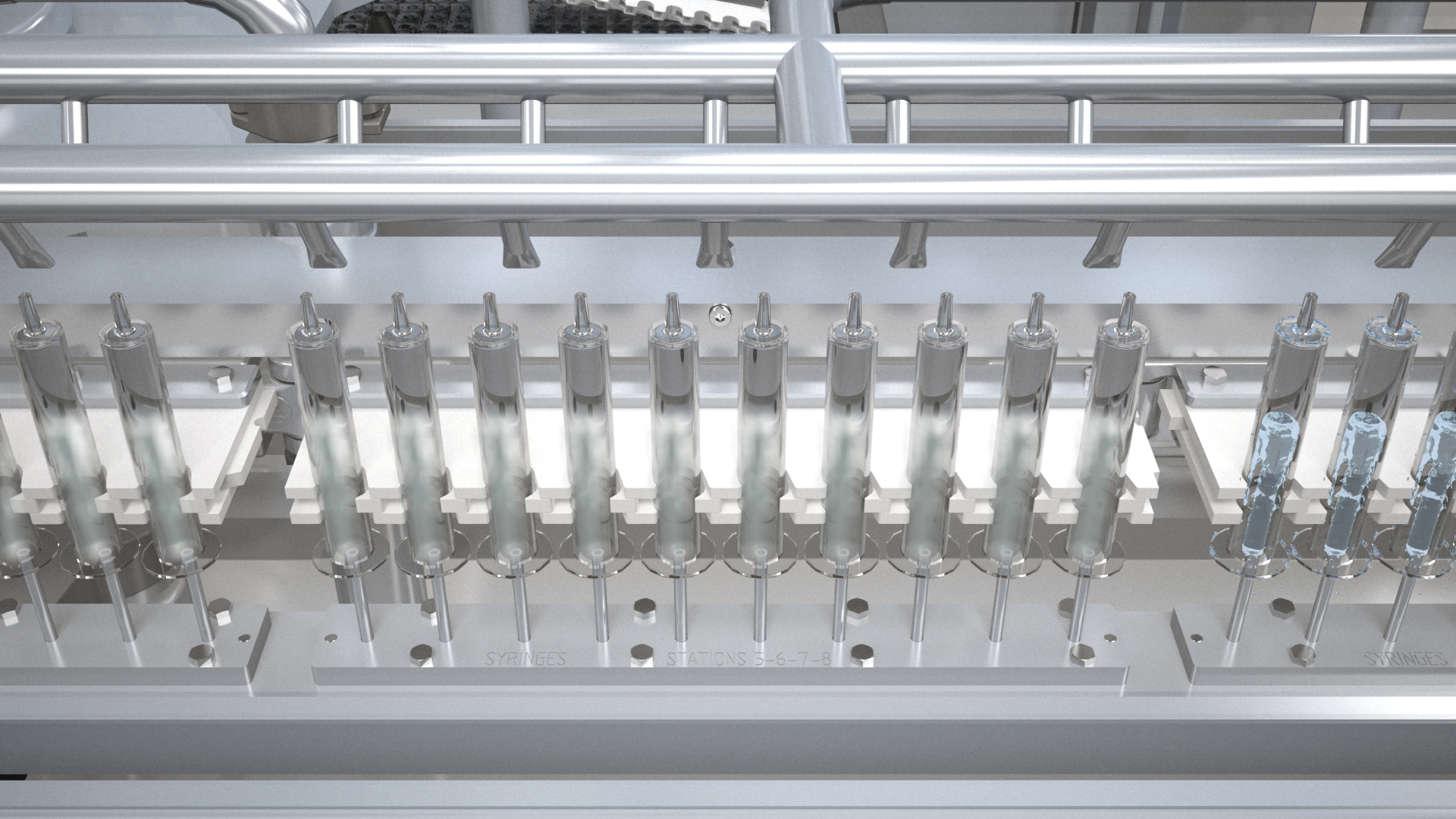

⦁ Syringes and Cartridge TUB and NEST preparation

⦁ Vials Trays

⦁ Container Nesting

⦁ Control of complete and conforming nest

⦁ Tyvek position and sealing

⦁ Sterile bag bagging

⦁ User-friendly and fast tool-free format change

⦁ Designed as a modular machine

Machine Output

100 to 400 BpM

Compatible containers

Contact us