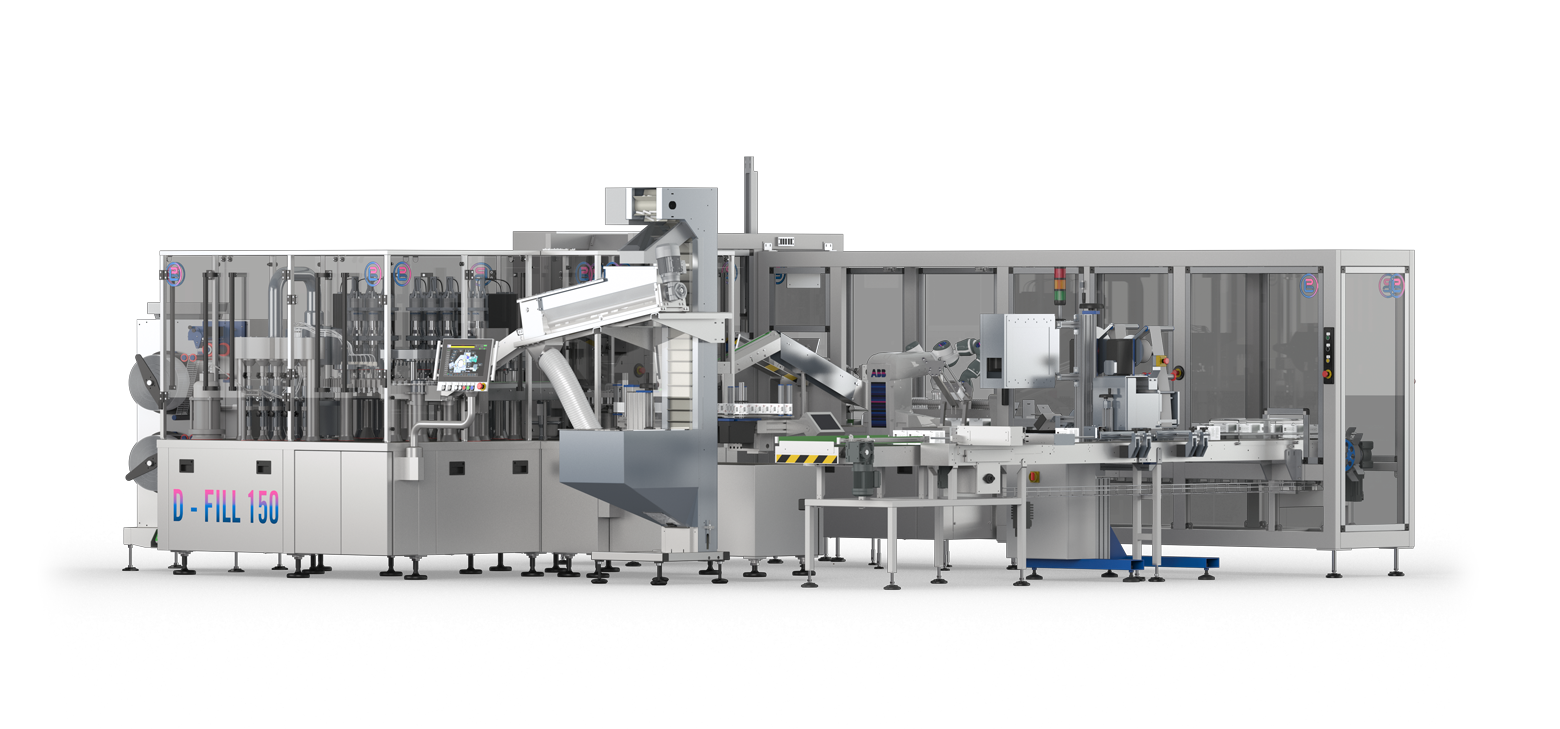

Overview

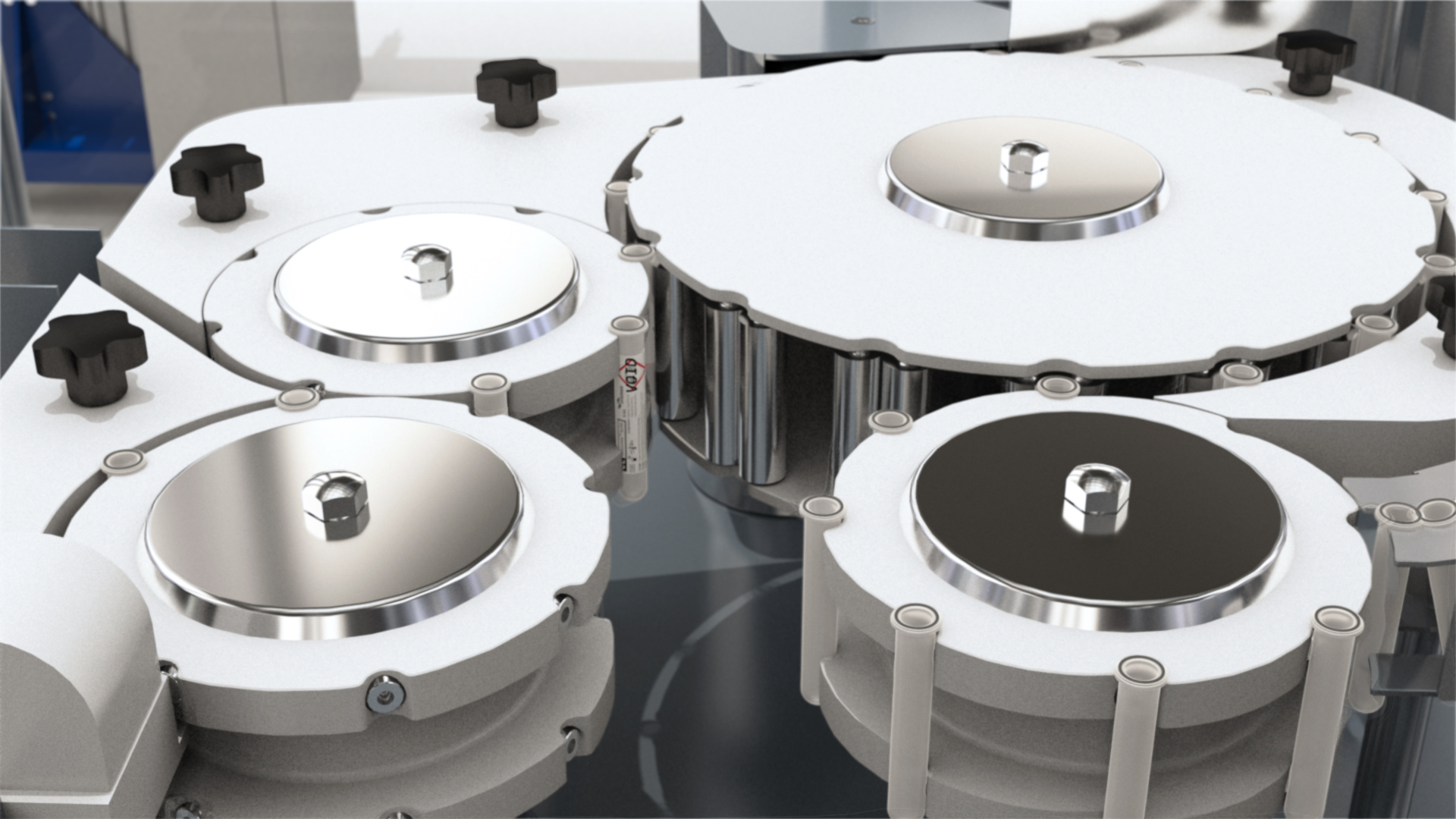

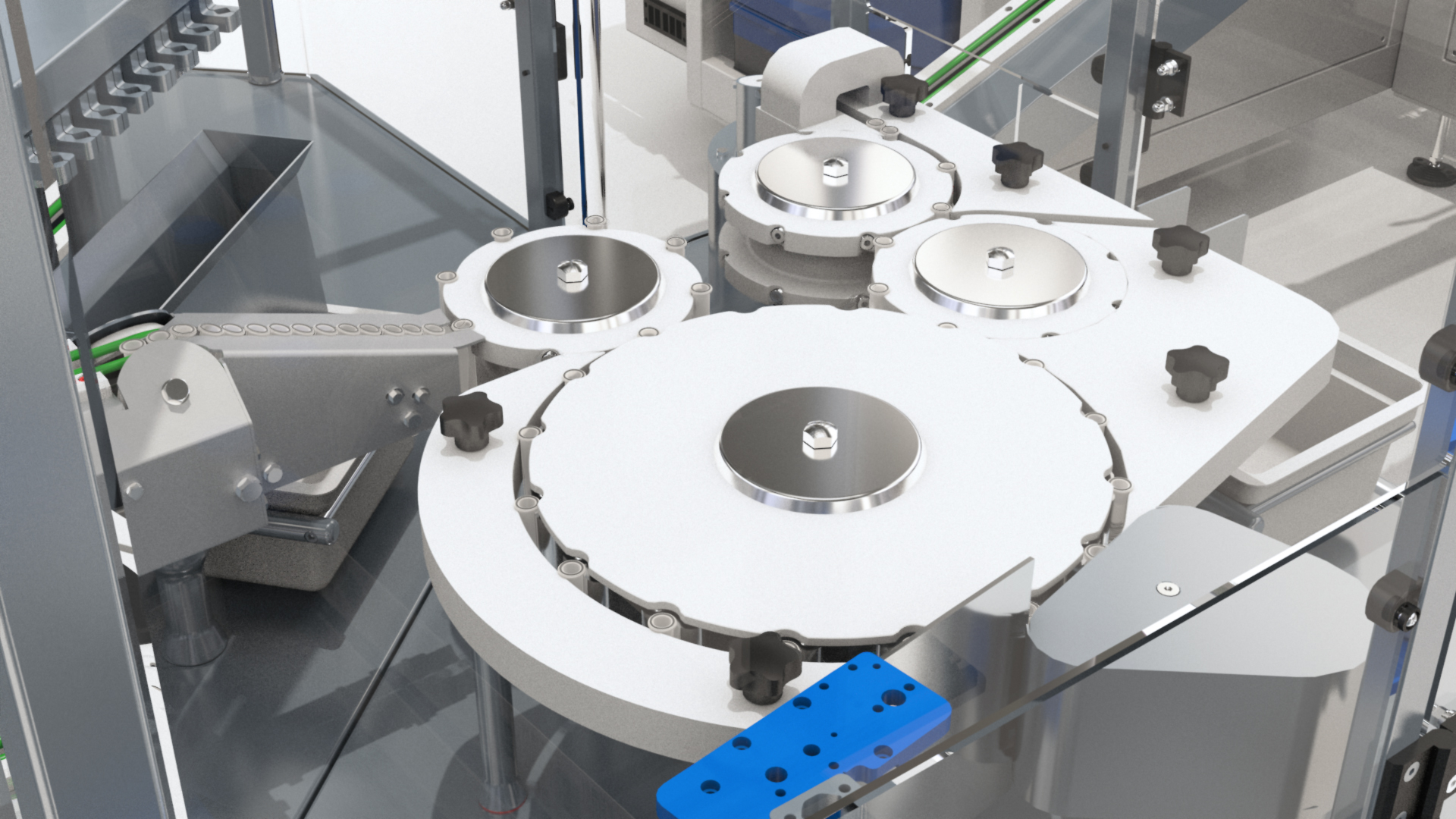

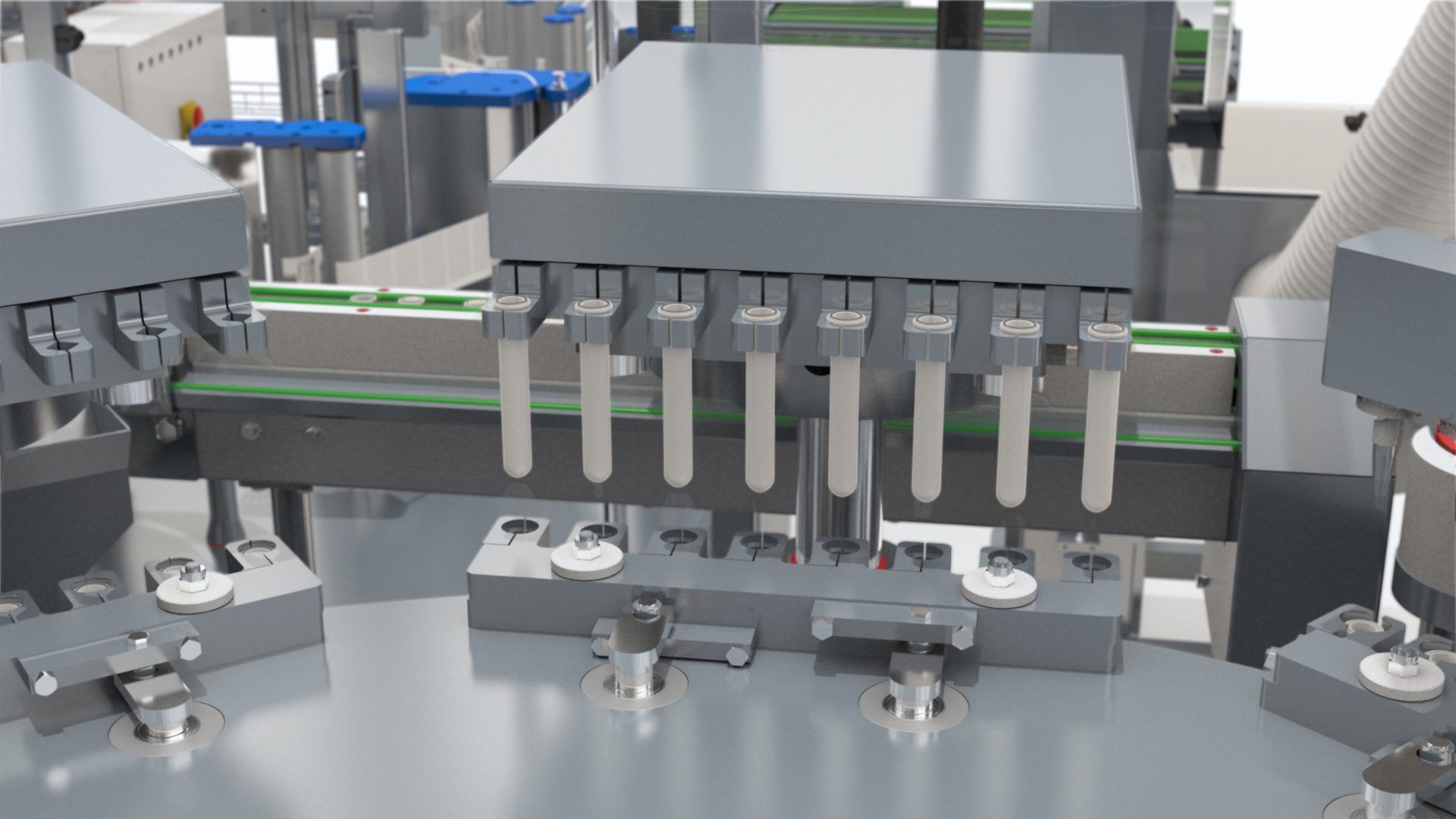

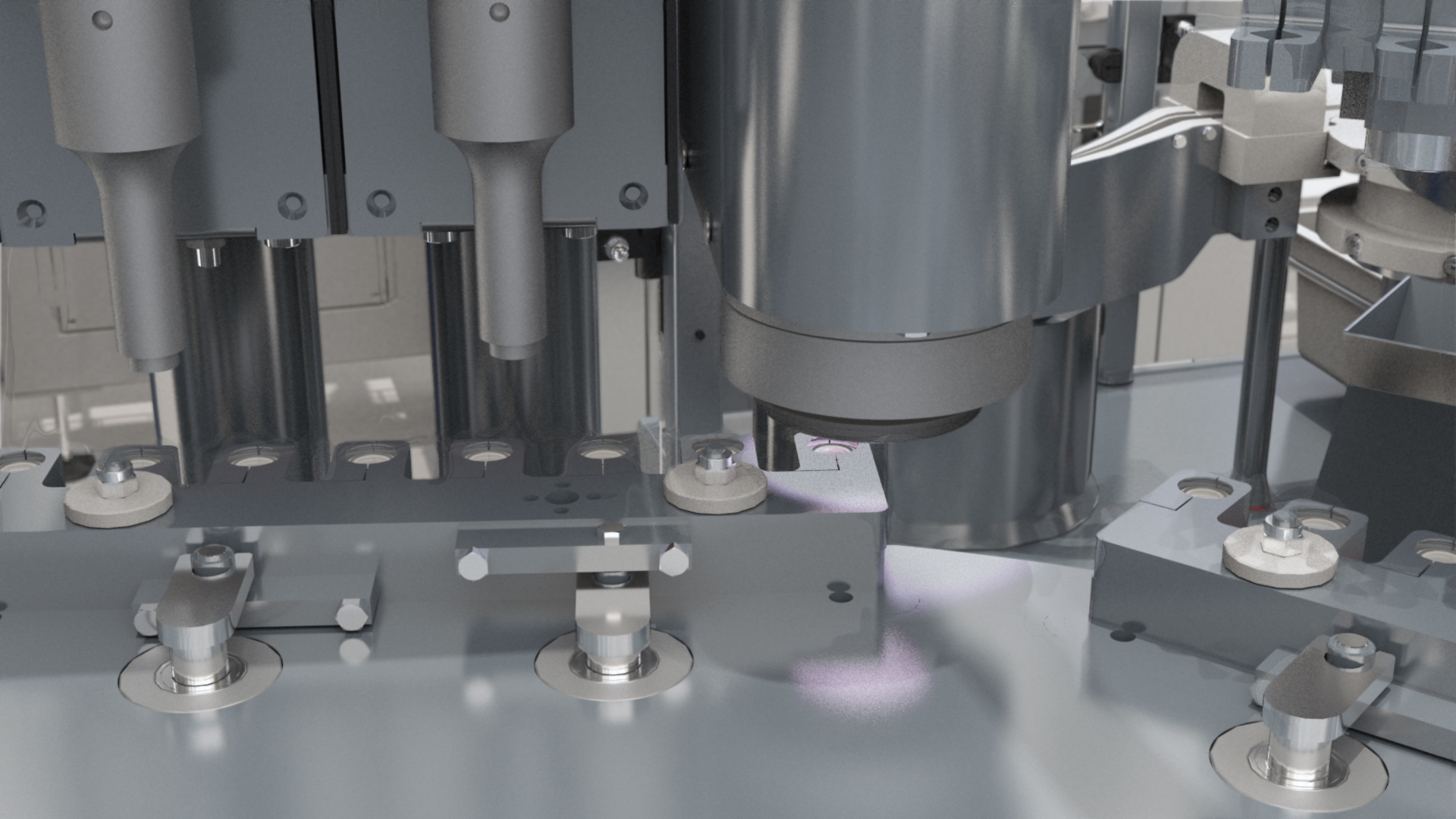

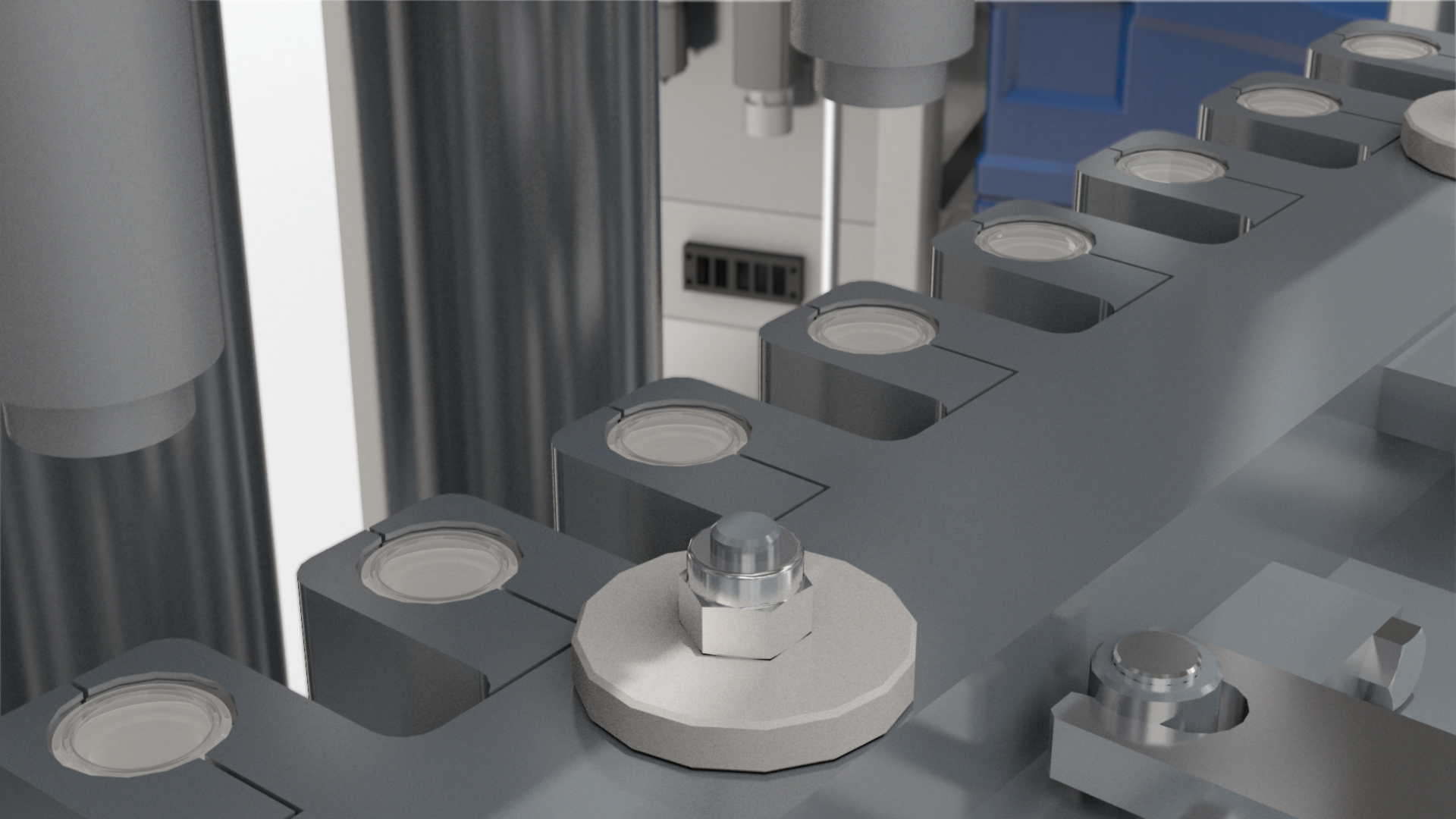

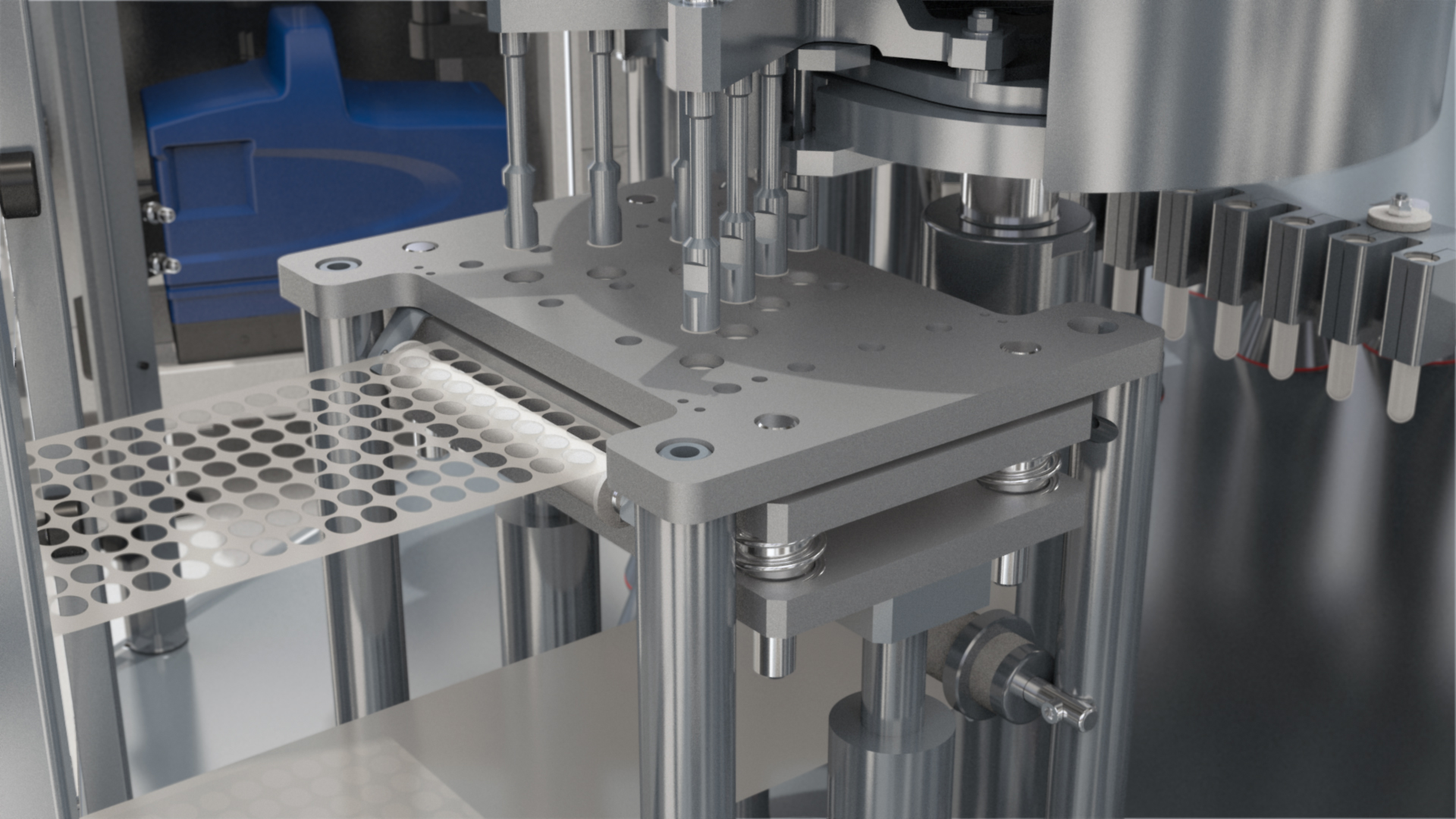

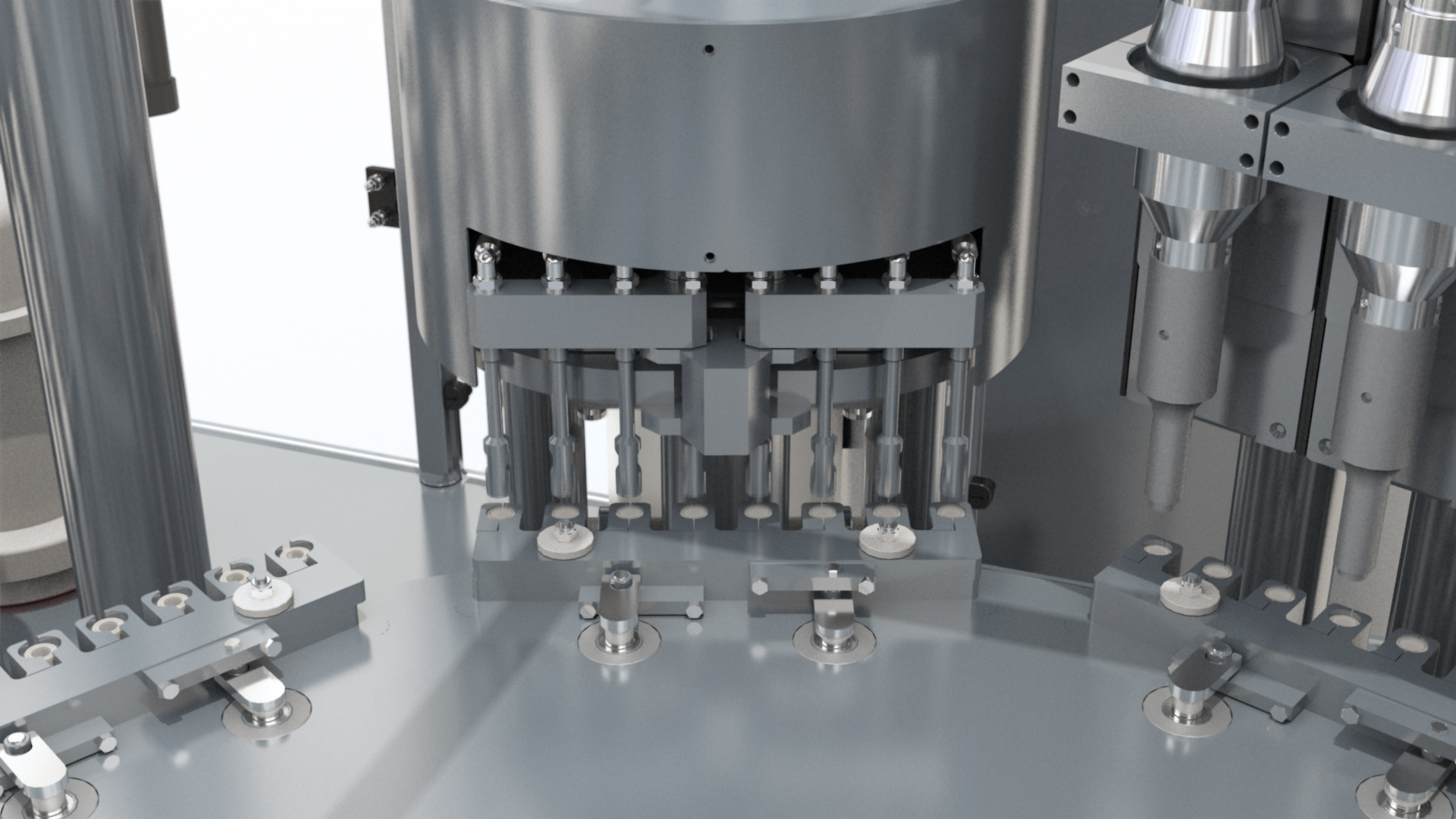

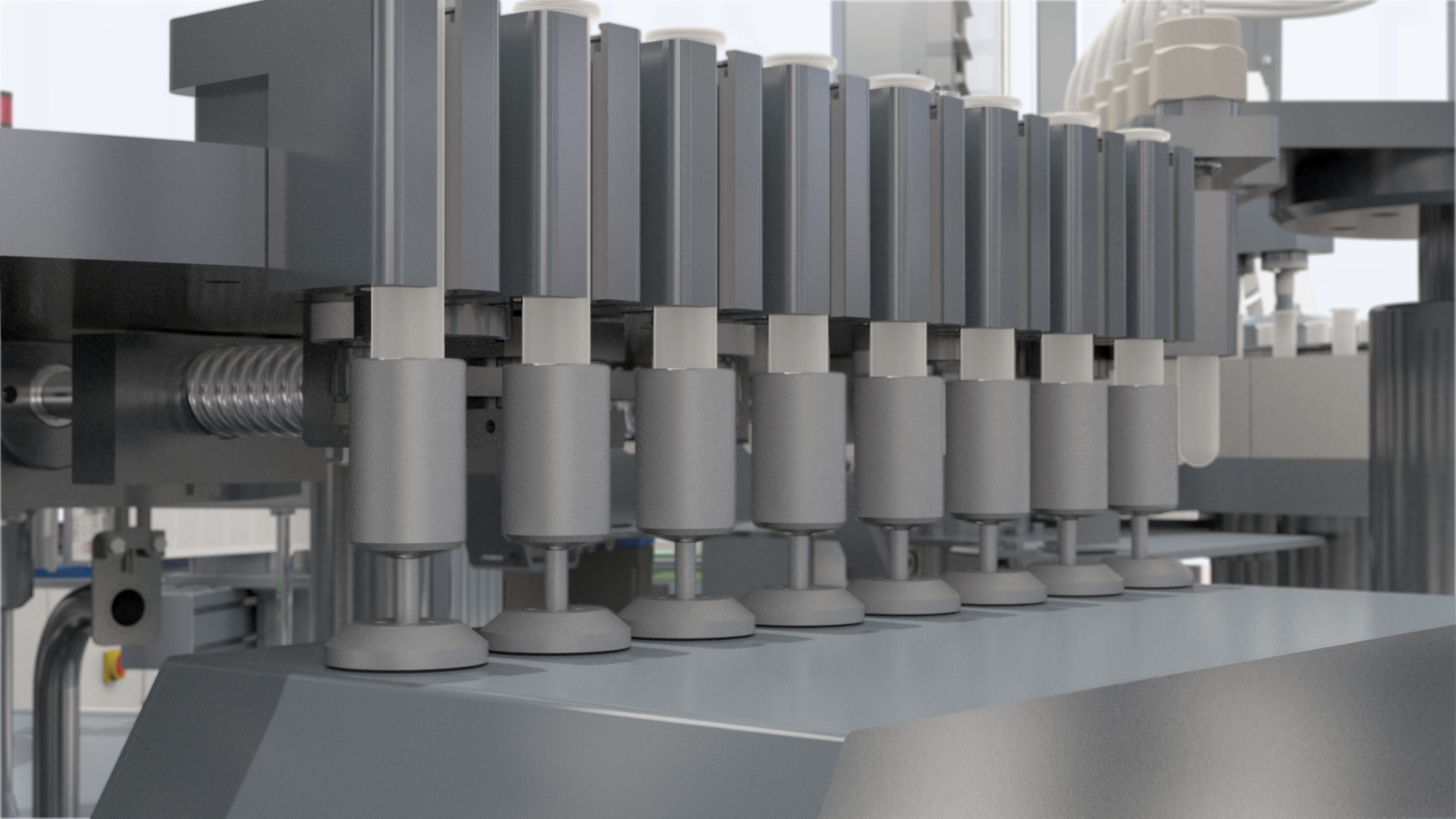

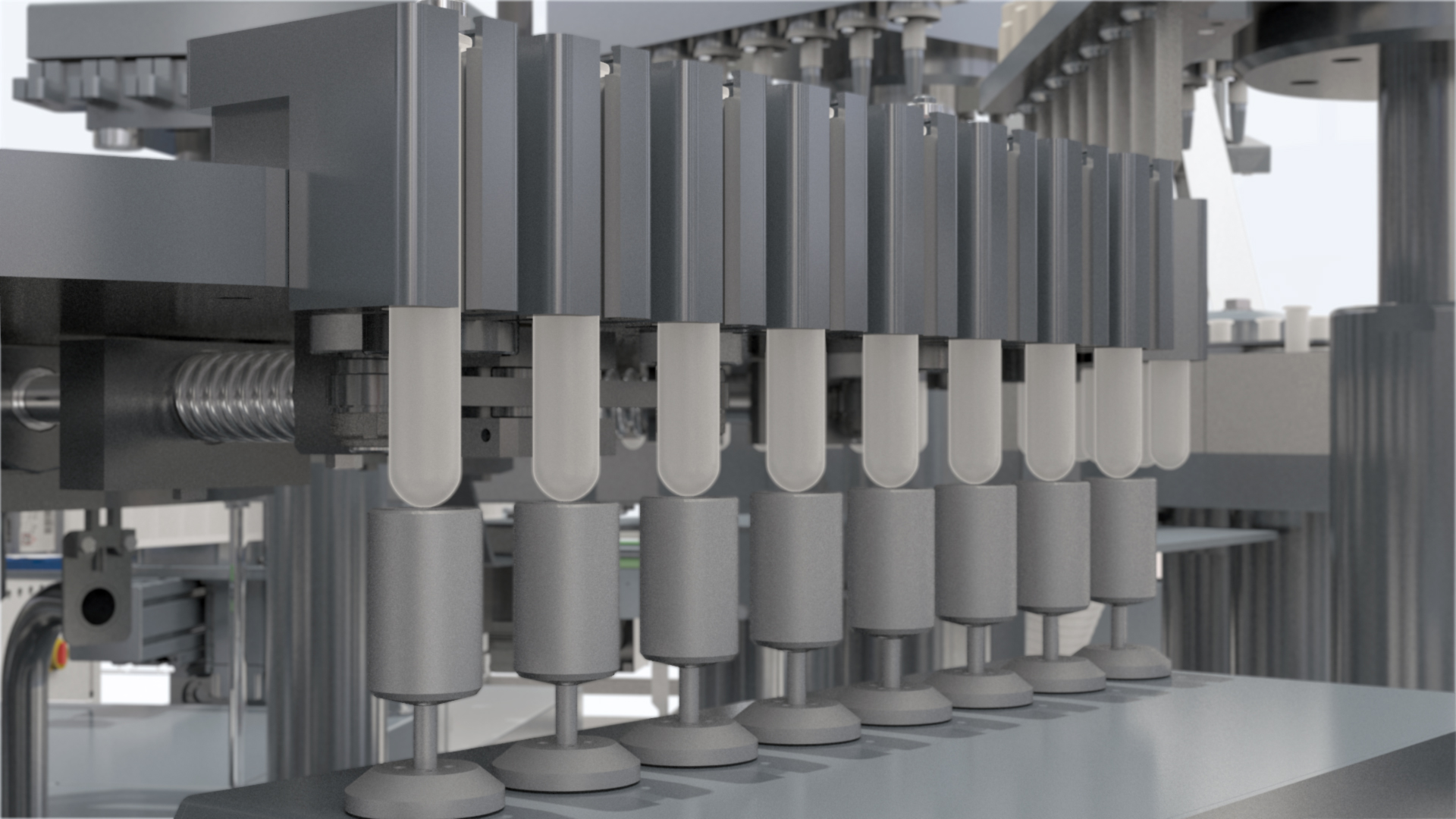

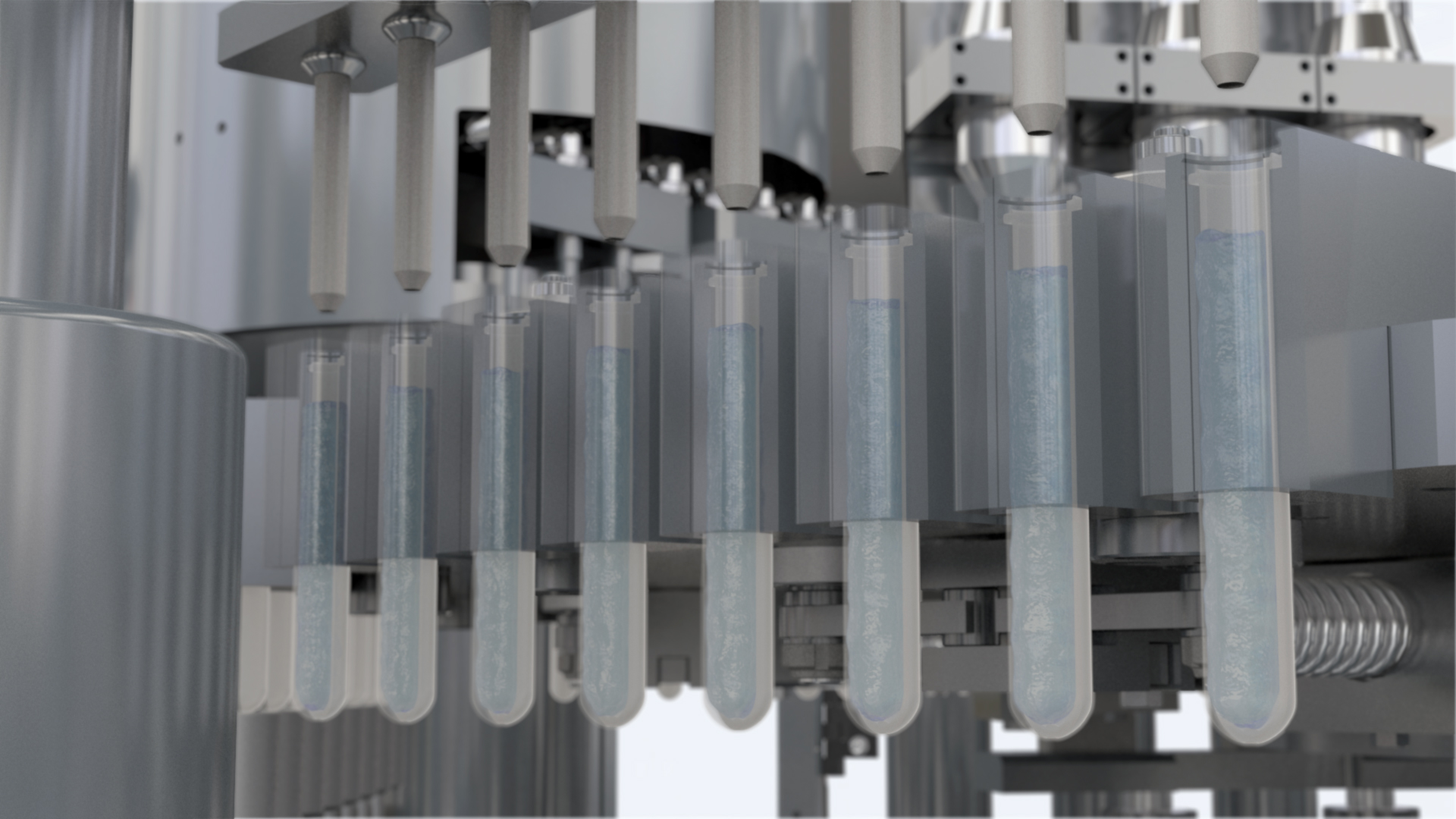

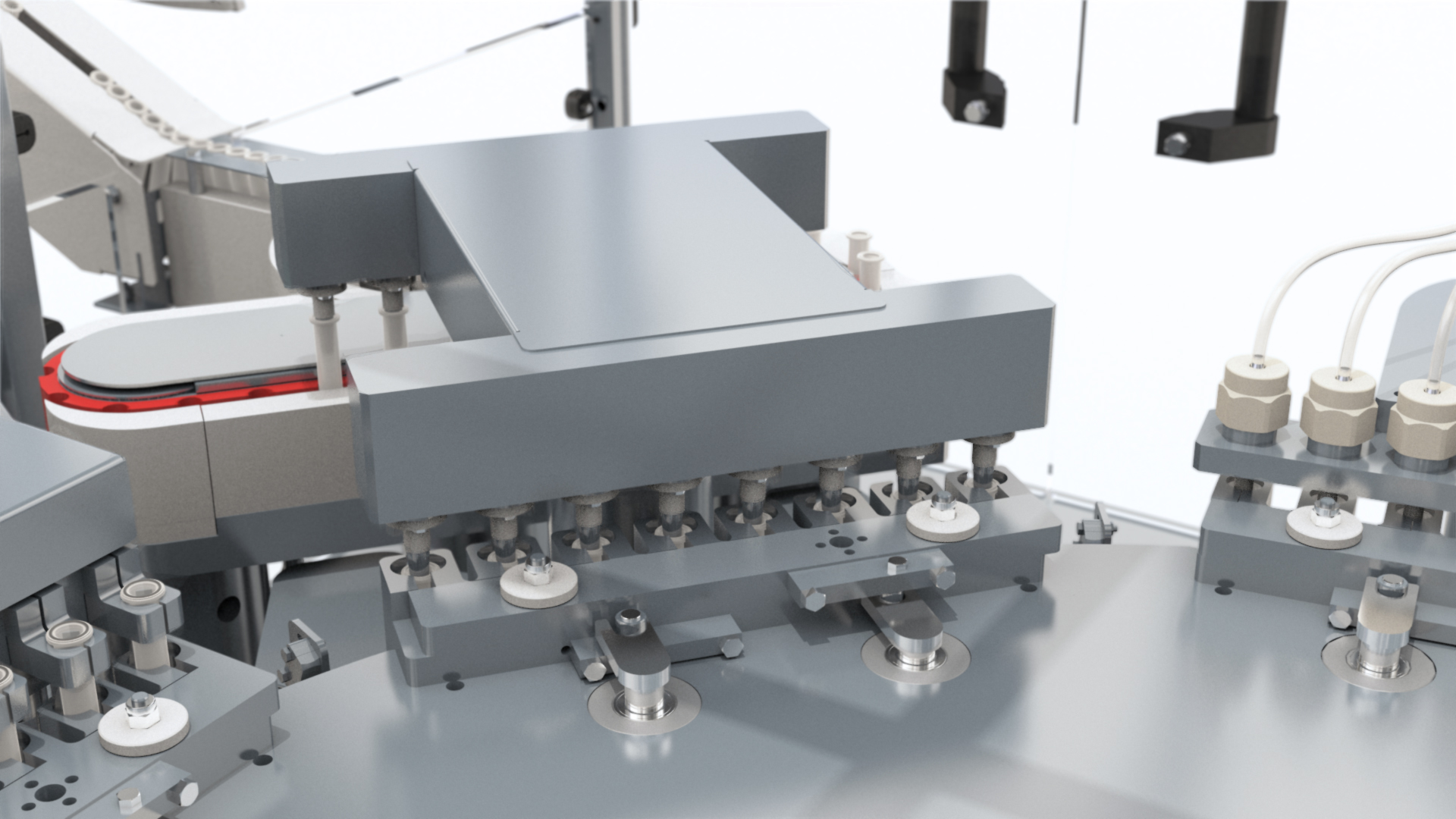

PBL Pharma Division custom designed, built, and successfully commissioned a complete line for diagnostic/chemical products in plastic, unstable containers. The line consists of three stations: filling system, ultrasonic welding, and cartoning system, fully integrated for maximum productivity. The line was designed based on high container instability and a high level of customization to meet client requirements. Each production process uses state-of-the-art equipment. Certified ISO 7 and ISO 5 using validated processes that are constantly monitored and controlled.

Main features

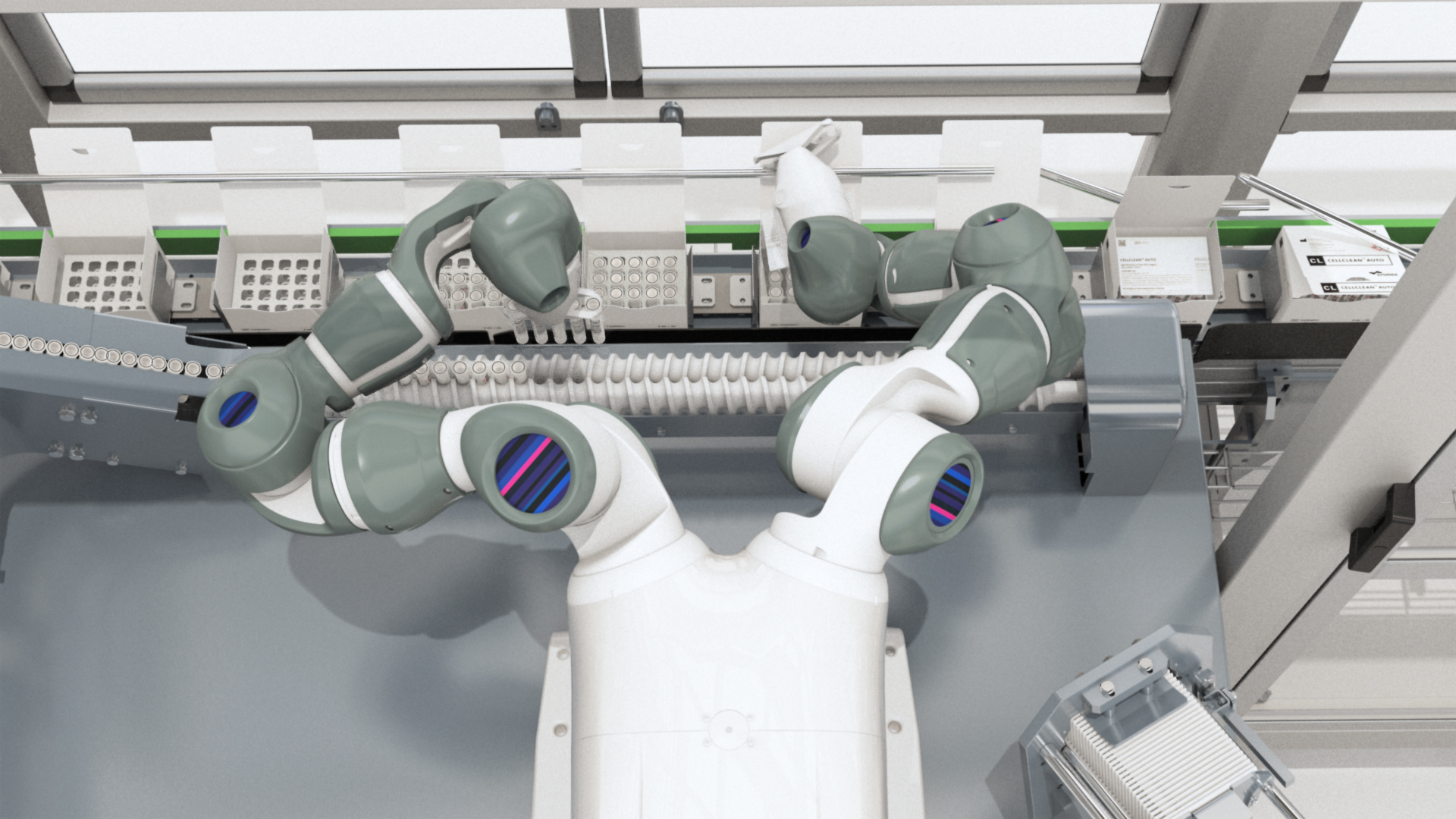

⦁ Customize loading/unloading system

⦁ IPC control (100% or statistical)

⦁ CIP/SIP system

⦁ Different filling options available

More features

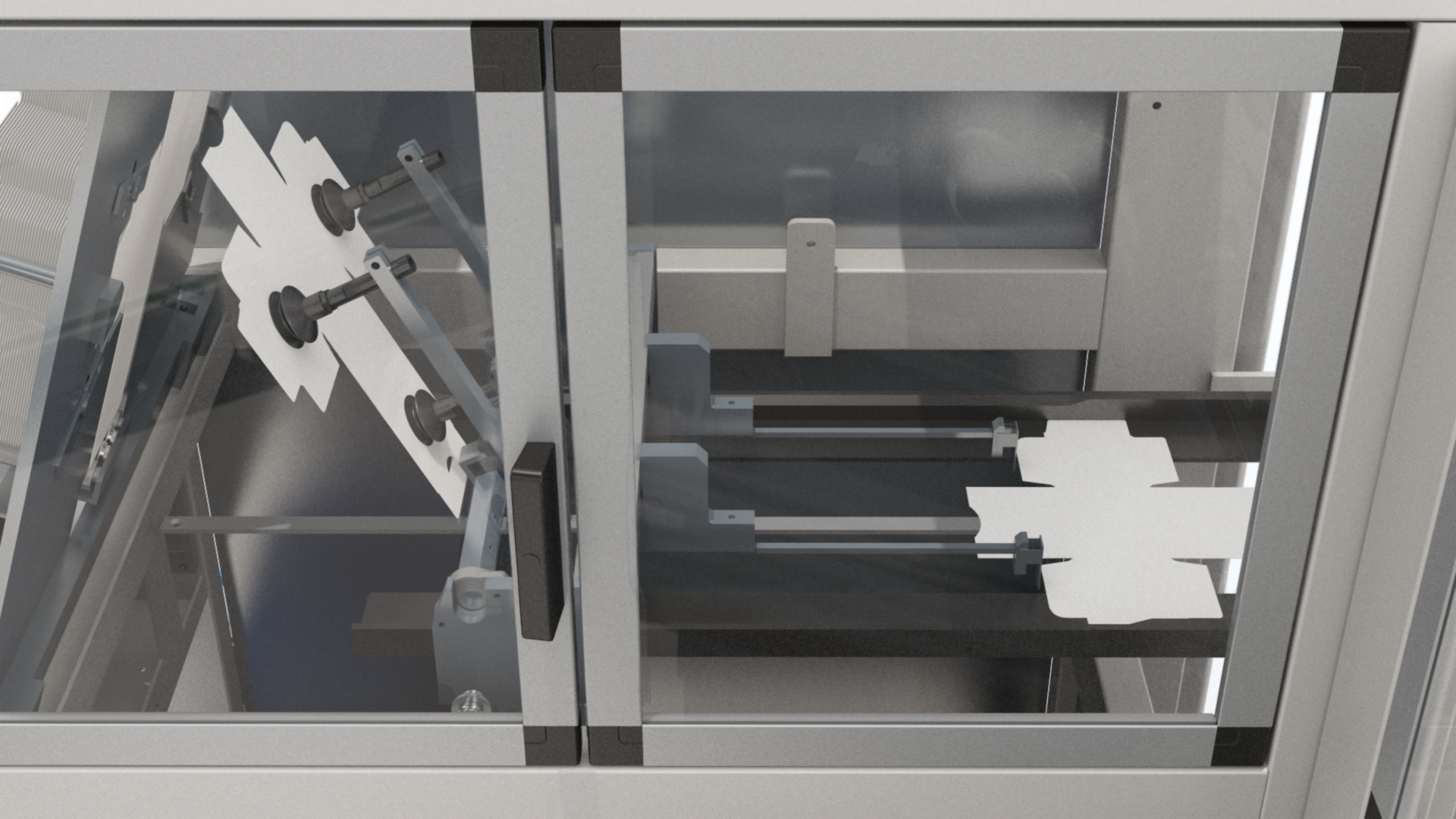

⦁ Different container closure systems available

⦁ Different monitoring functions (eg. monitoring of fill volume, seal integrity, etc)

⦁ User-friendly and fast tool-free format change

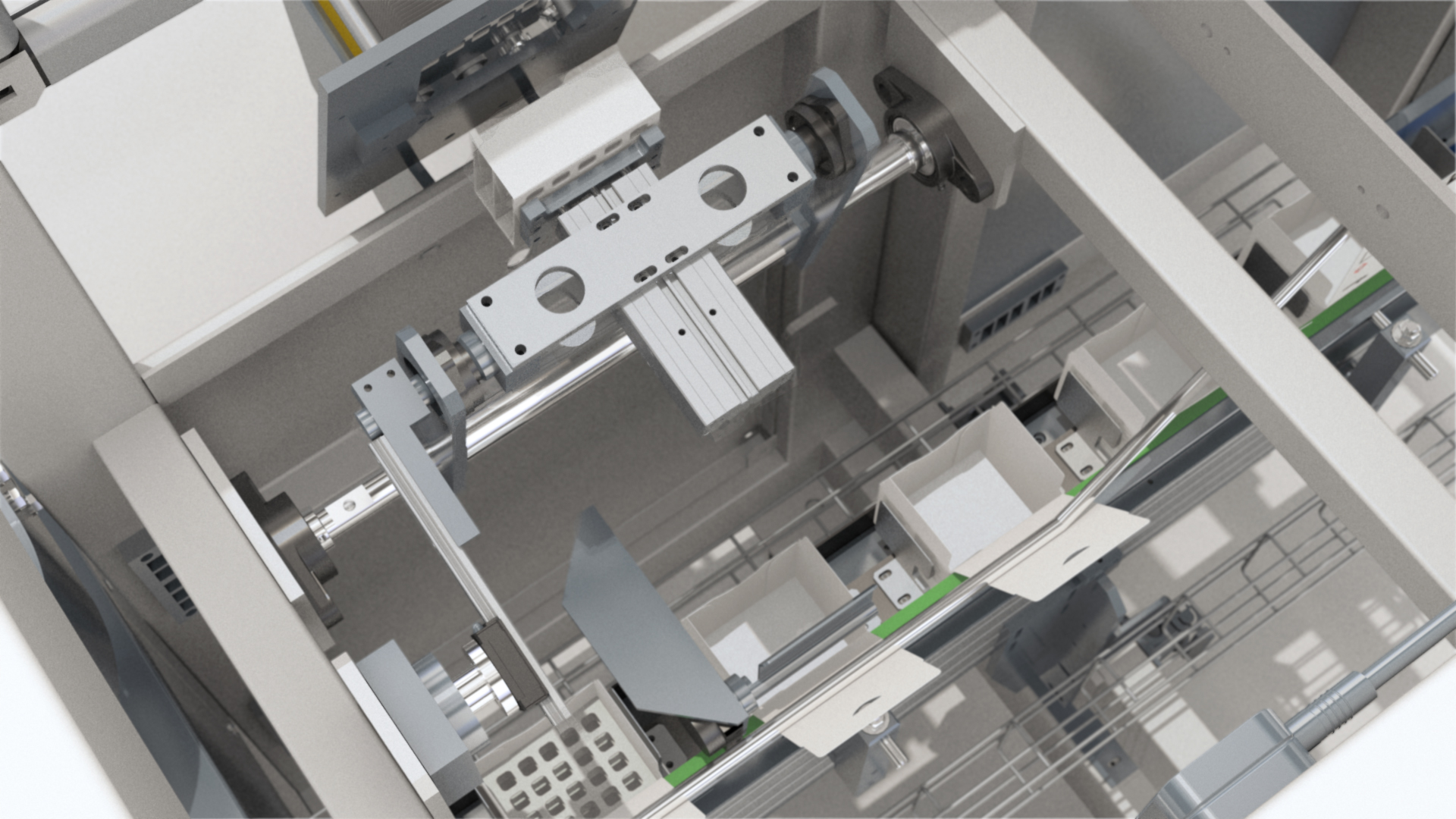

⦁ Designed as a modular machine

⦁ Custom-designed system

⦁ High flexibility for carton and box handling

Machine Output

20 to 400 BpM

Compatible containers

Contact us