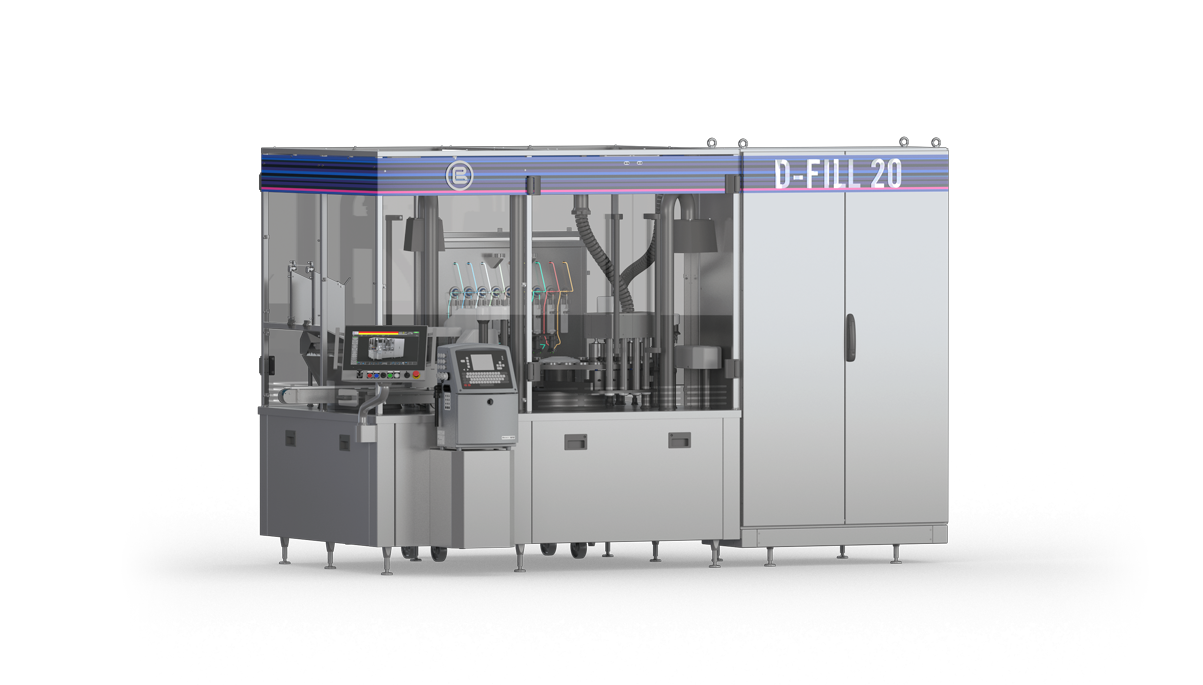

Overview

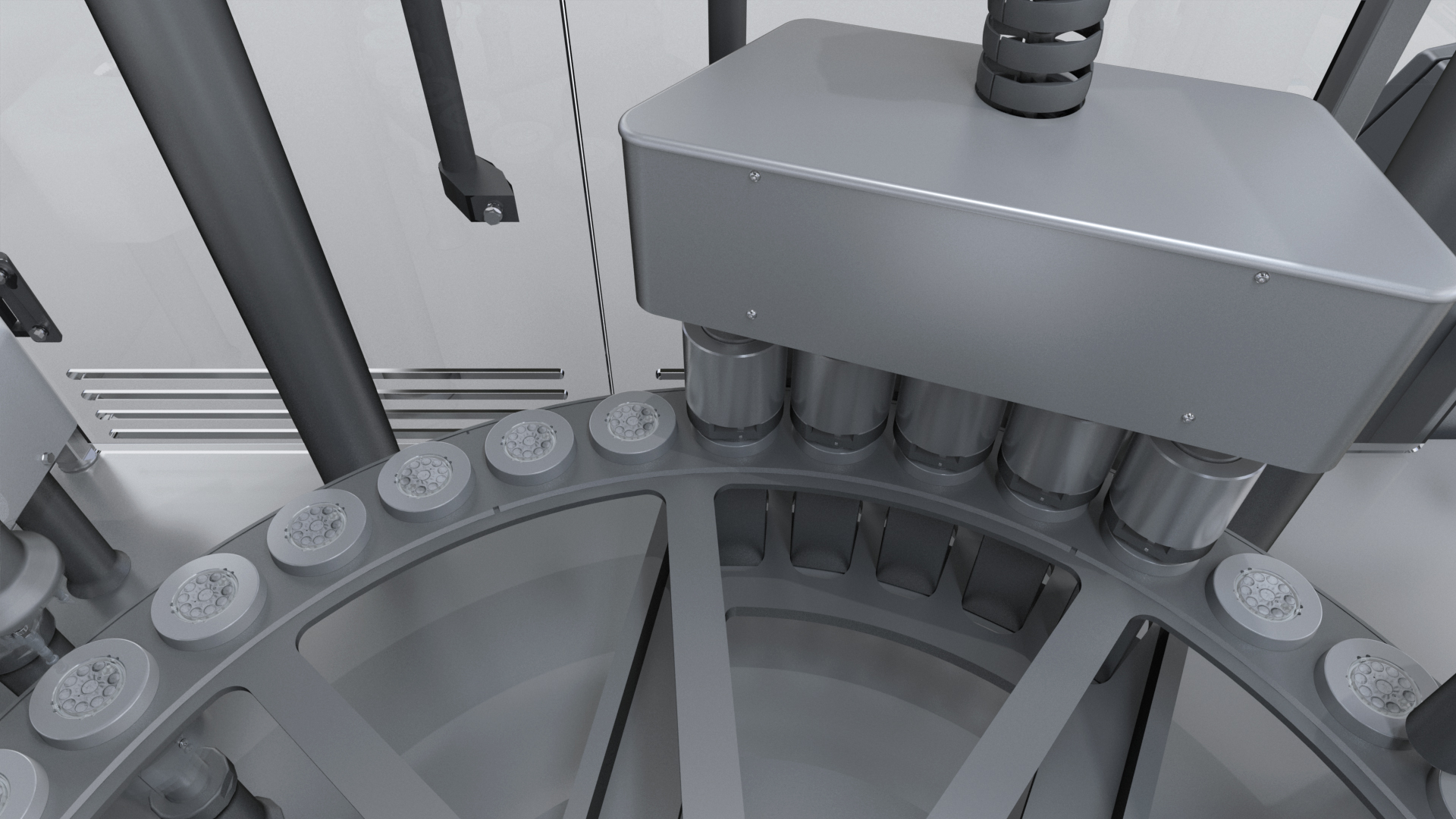

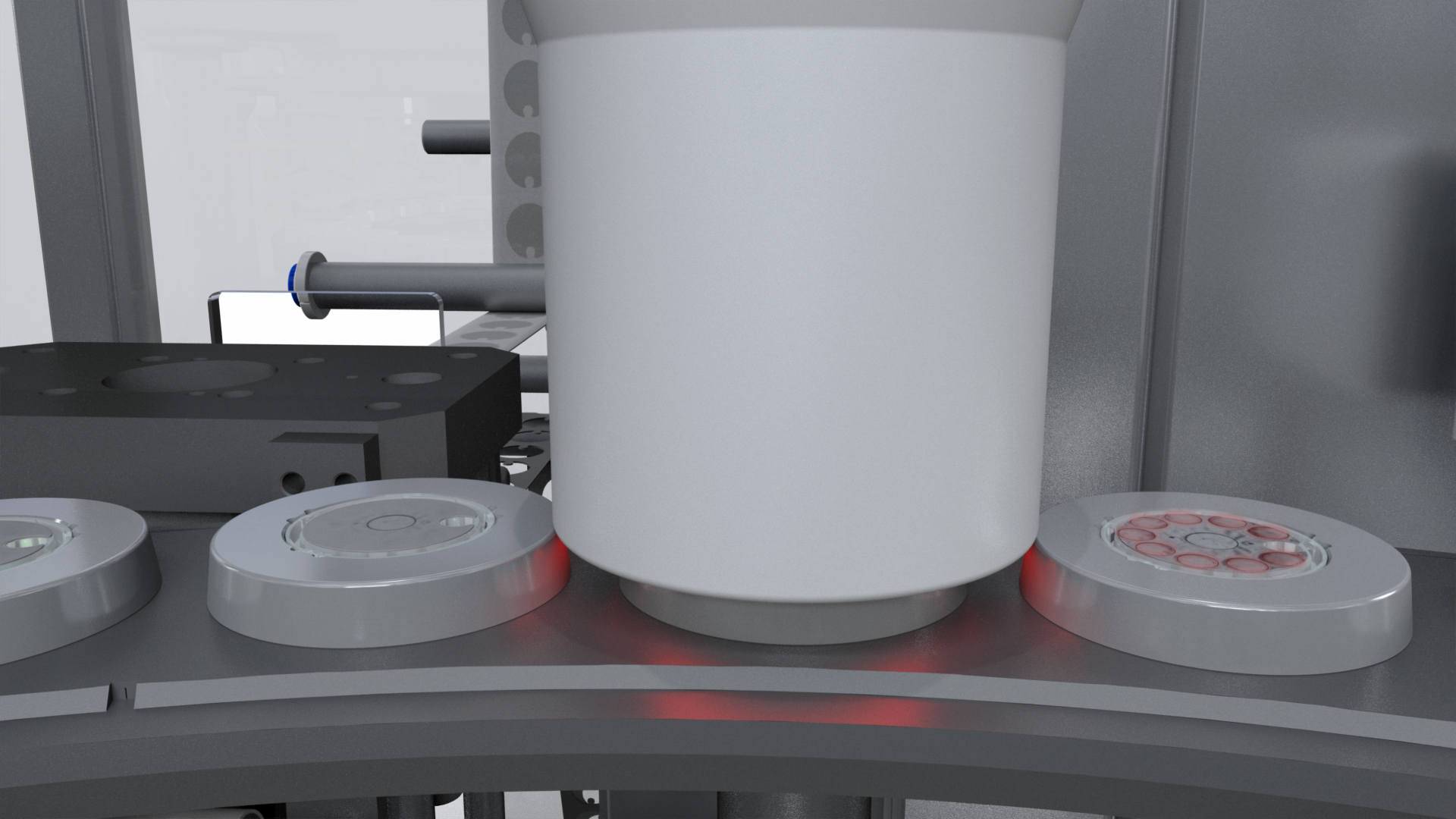

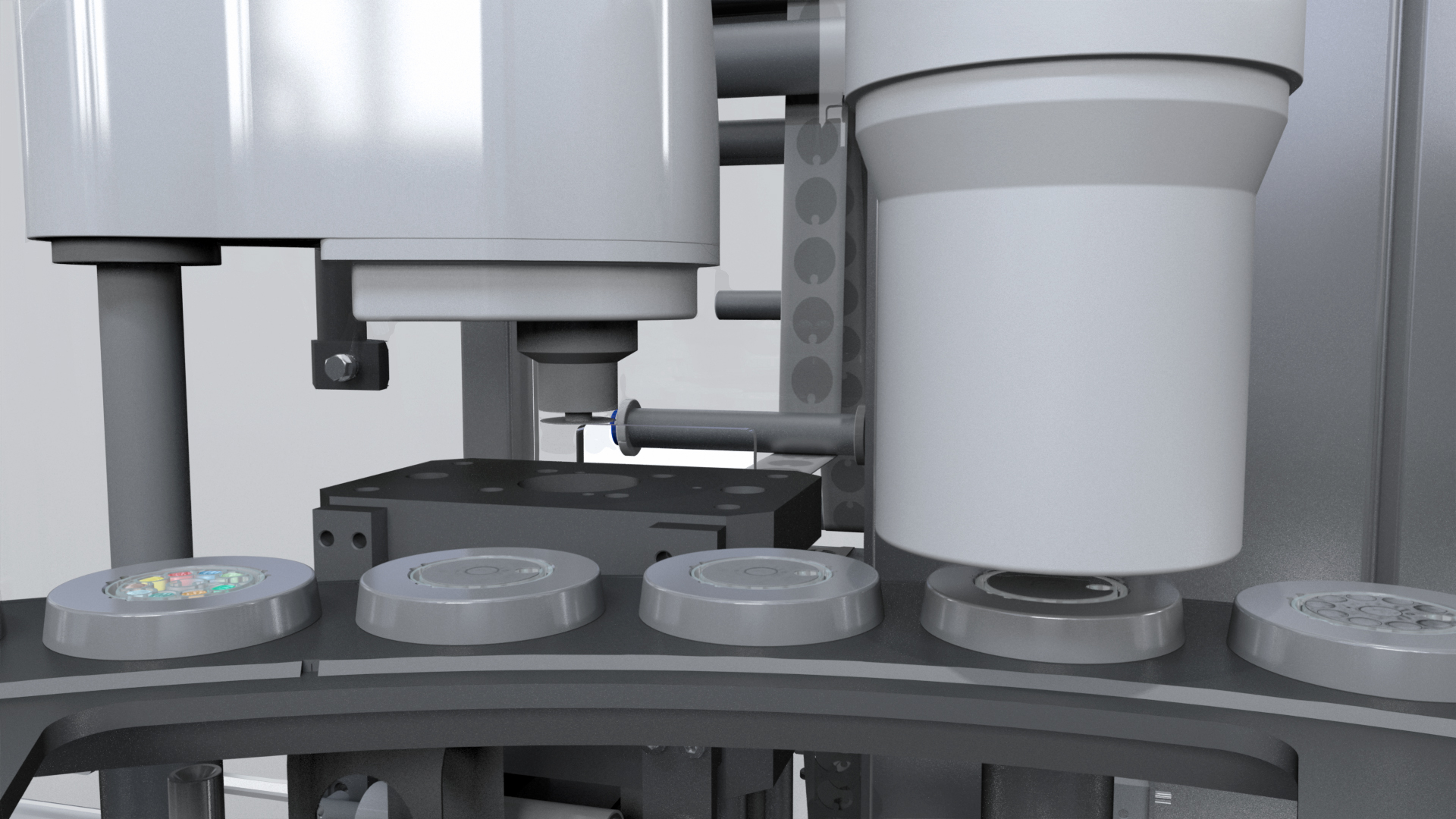

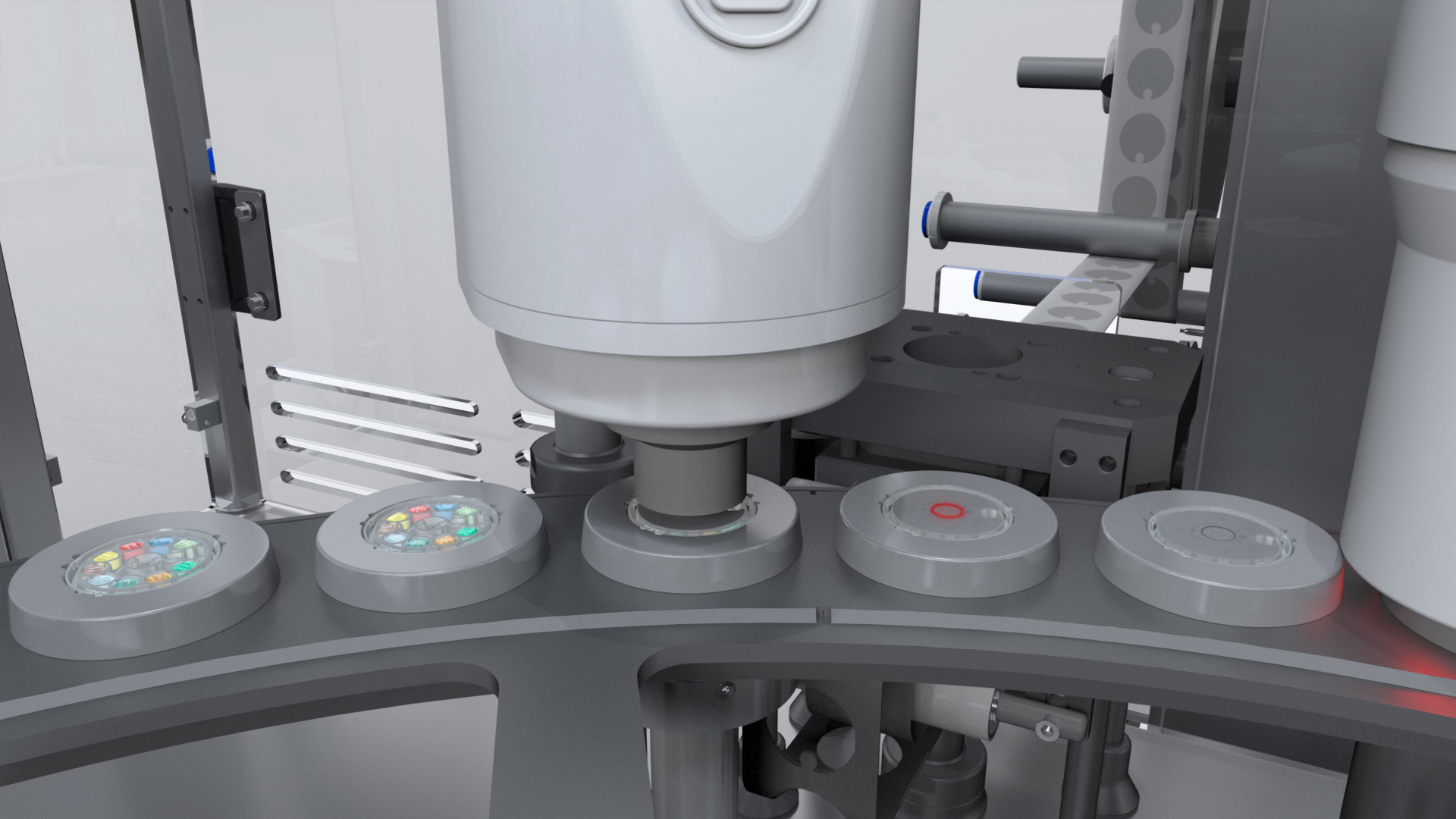

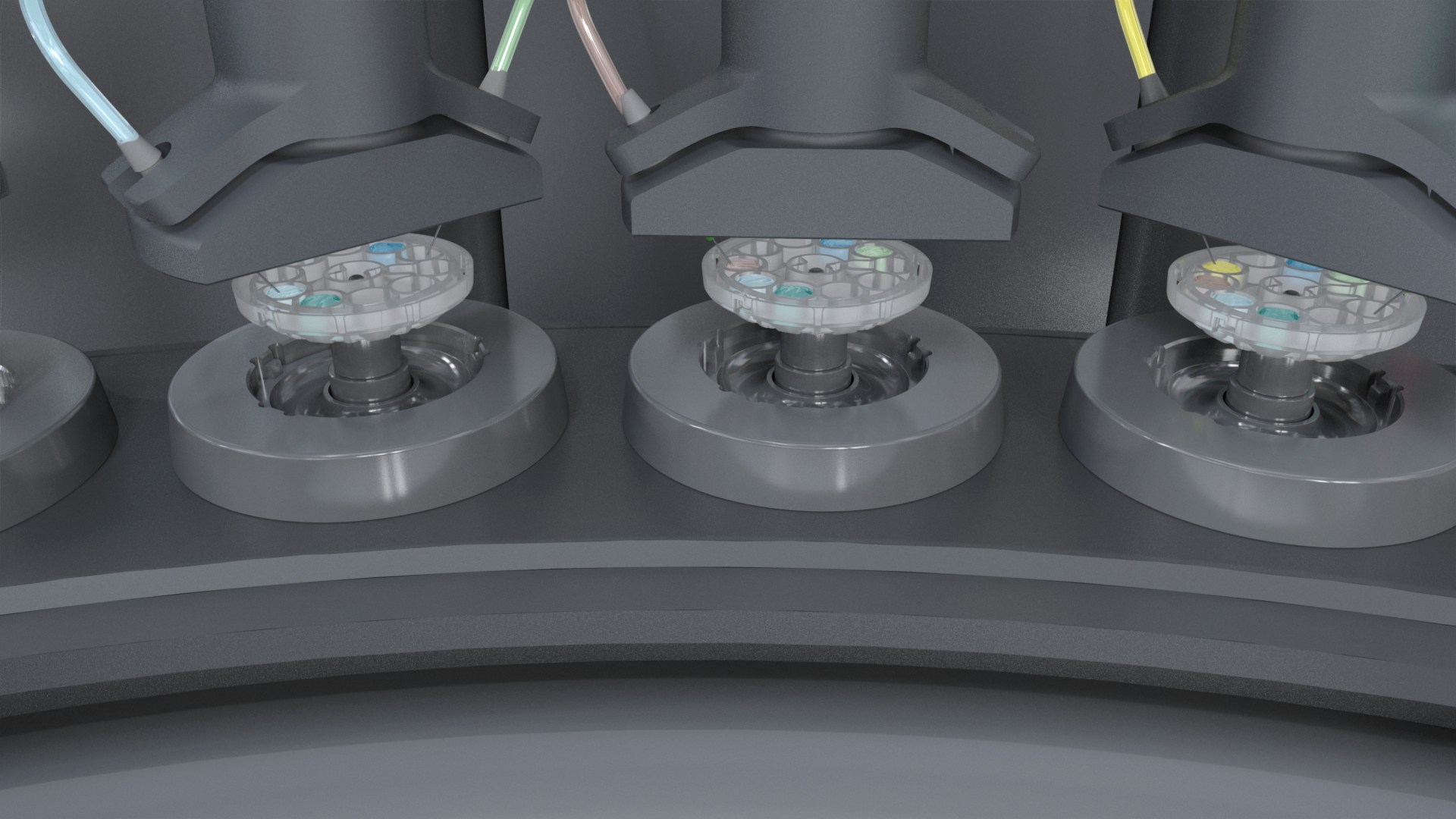

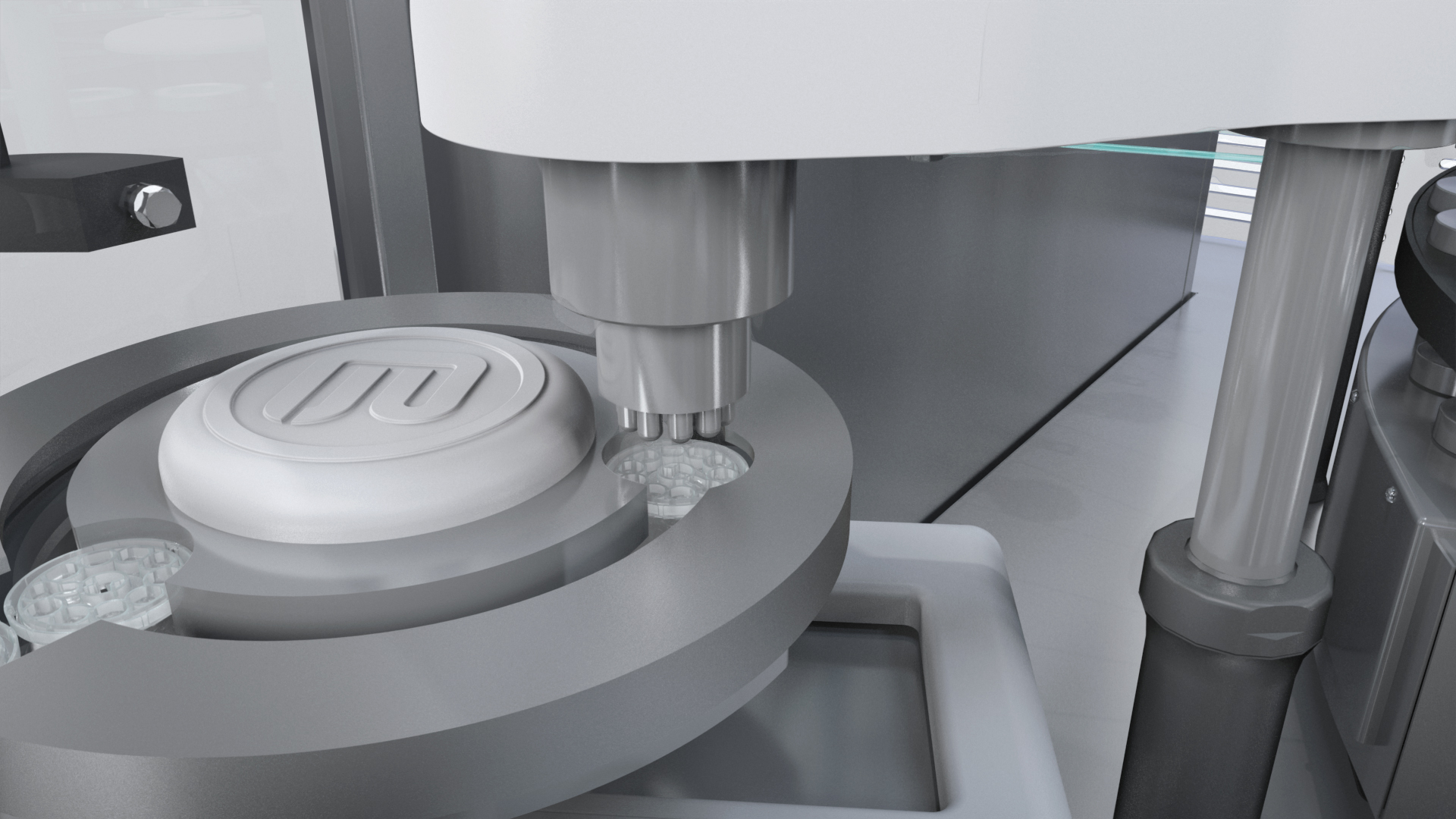

Our Pharma Division offers custom designed filling and closing machines for diagnostic containers. Filling, closing and several controls are performed during 100% in-line production. All controls are perfectly integrated to offer our clients exceptional equipment. For the end-user, this results in fewer rejects and the best production performances. Each phase of the production process is conducted with the latest generation equipment; certified ISO 7 and ISO 5 using validated processes that are constantly monitored and controlled.

Main features

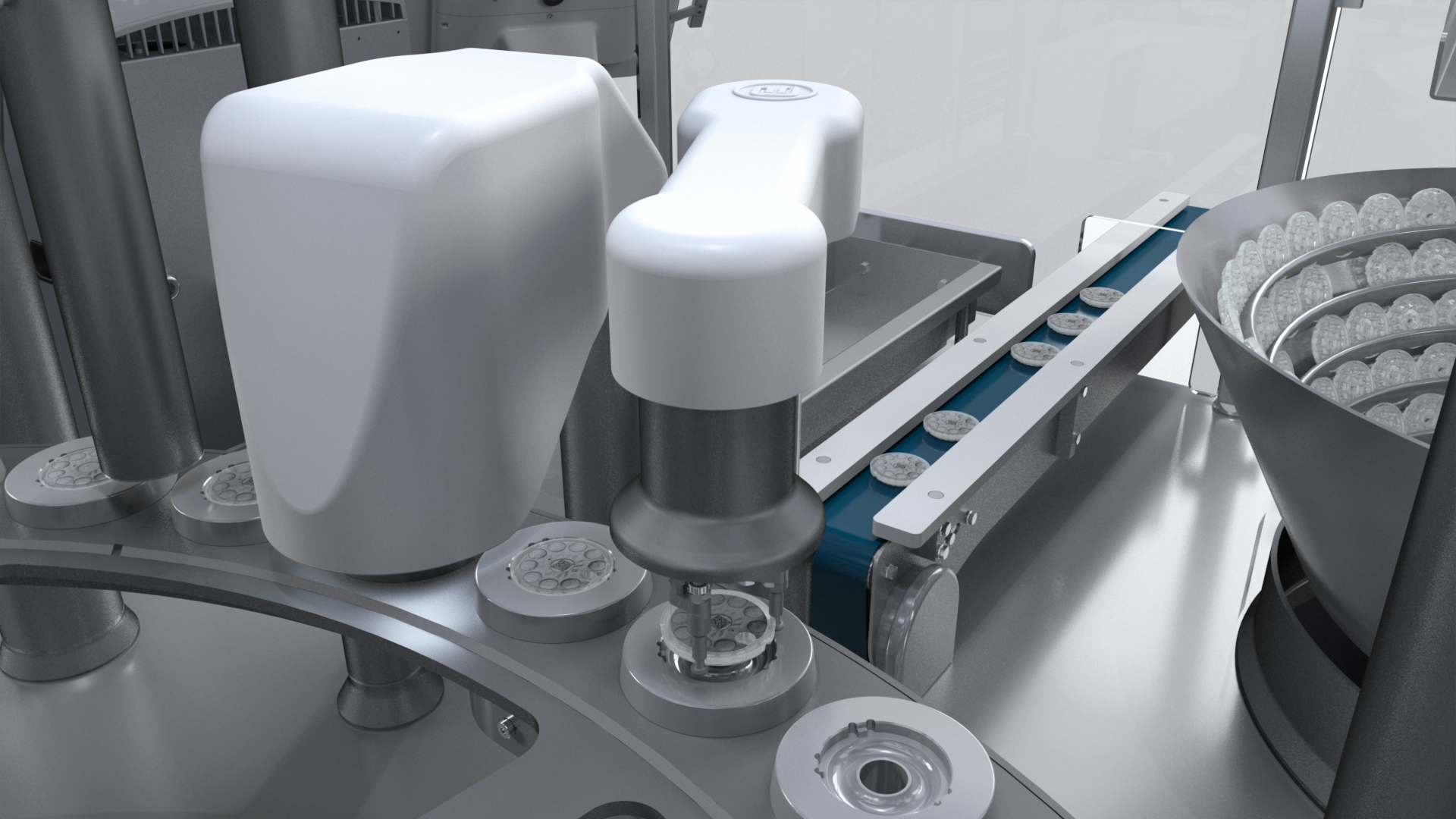

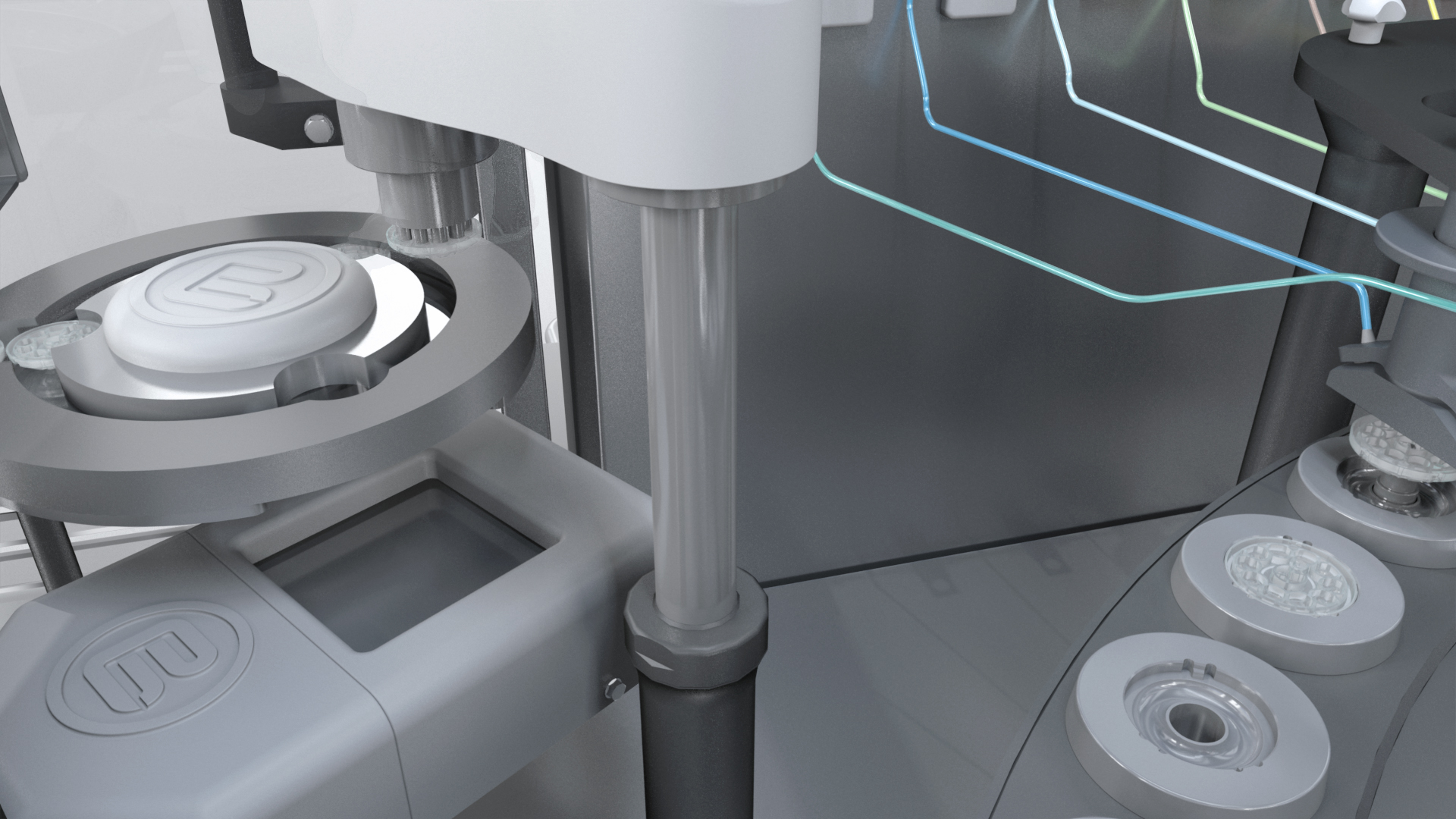

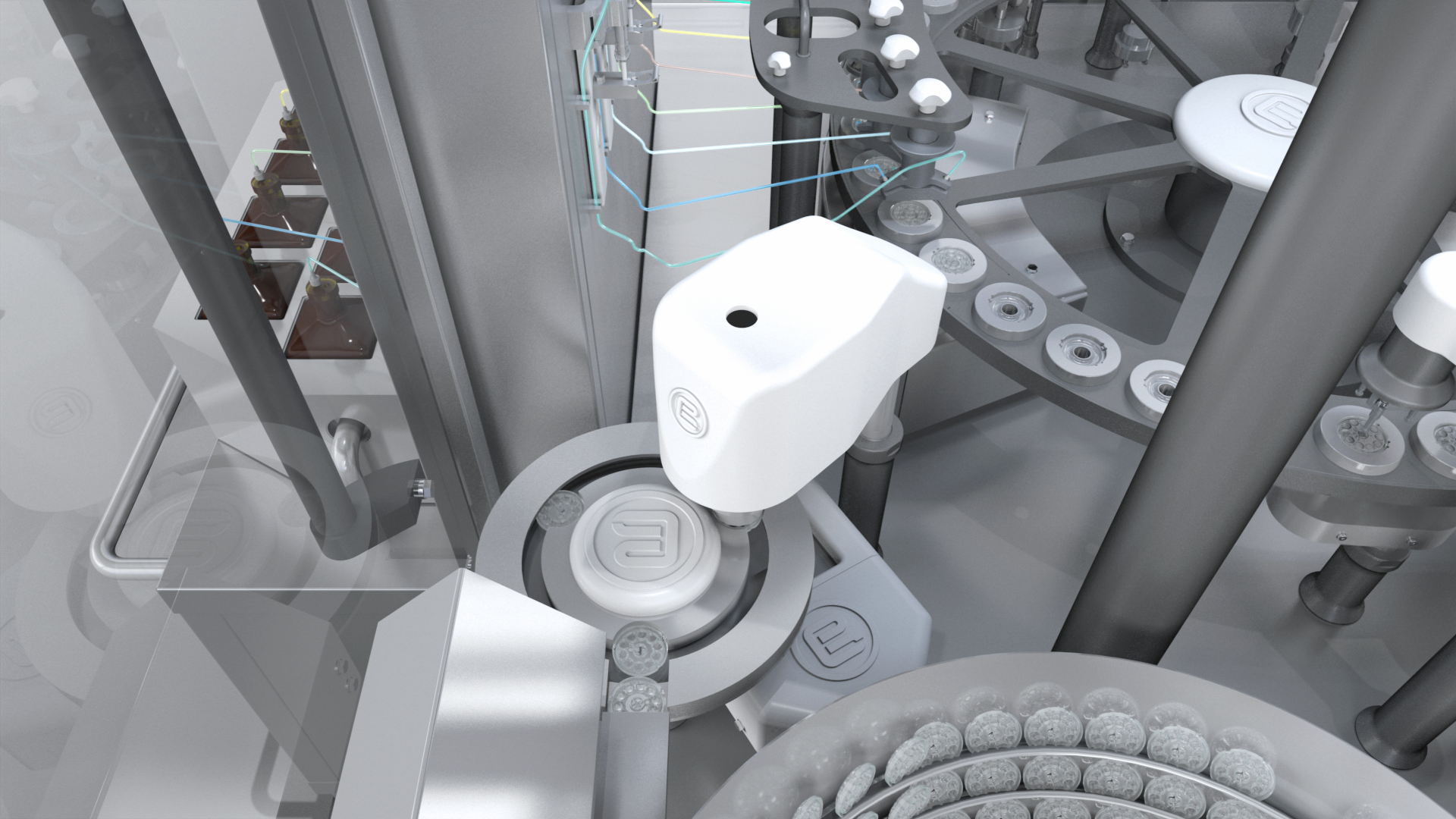

⦁ Pick & place loading/unloading

⦁ Camera orientation system

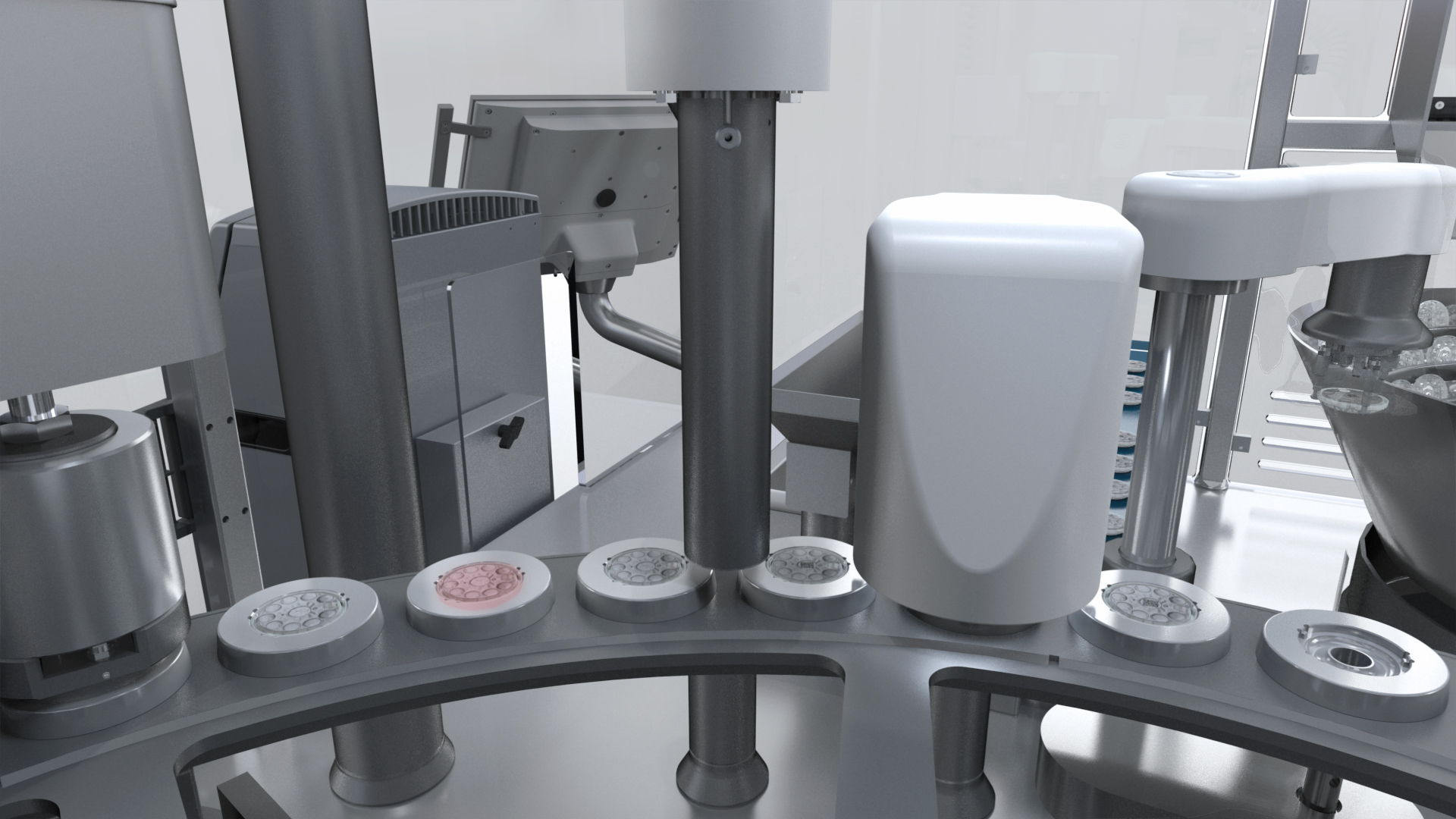

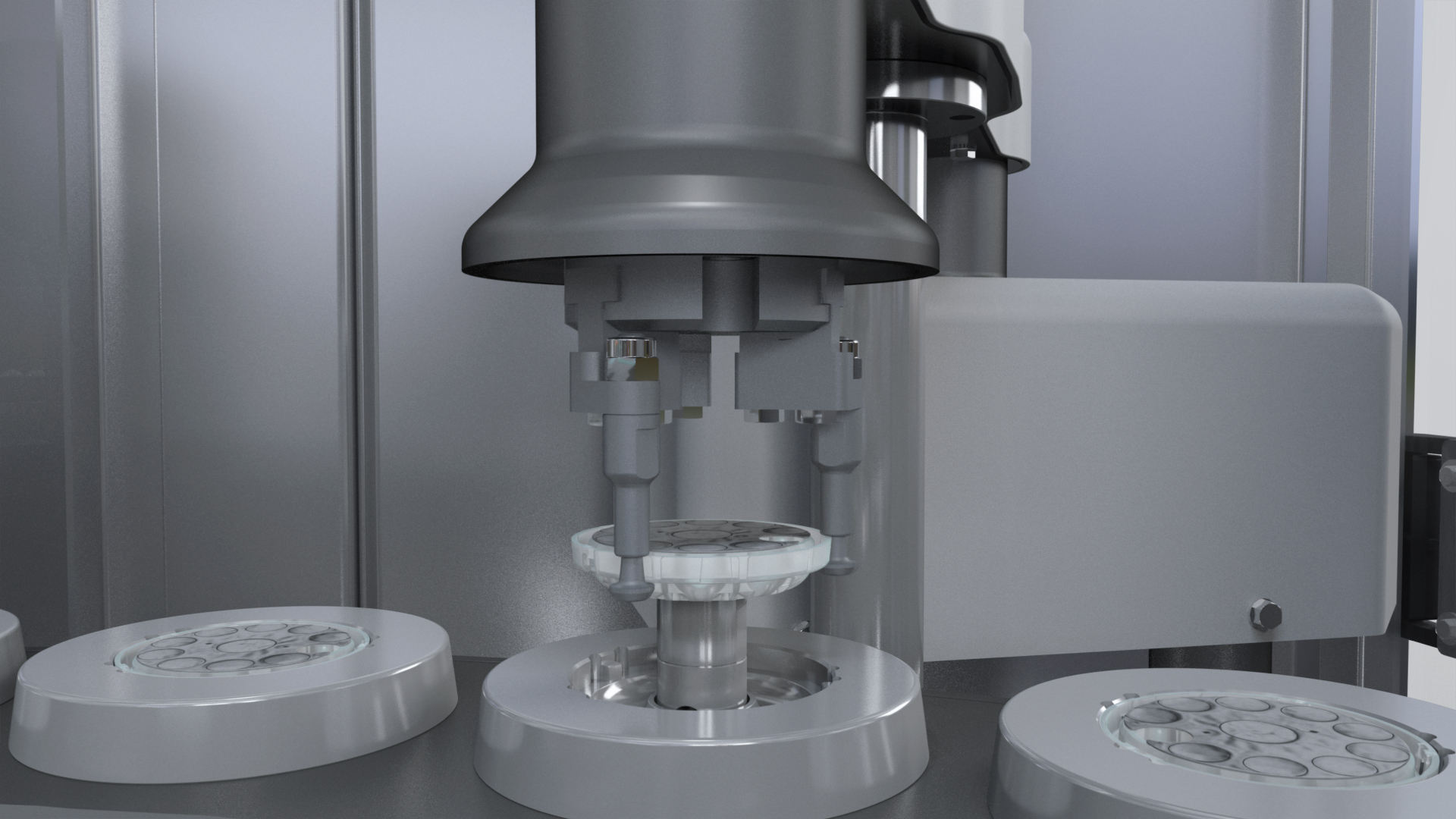

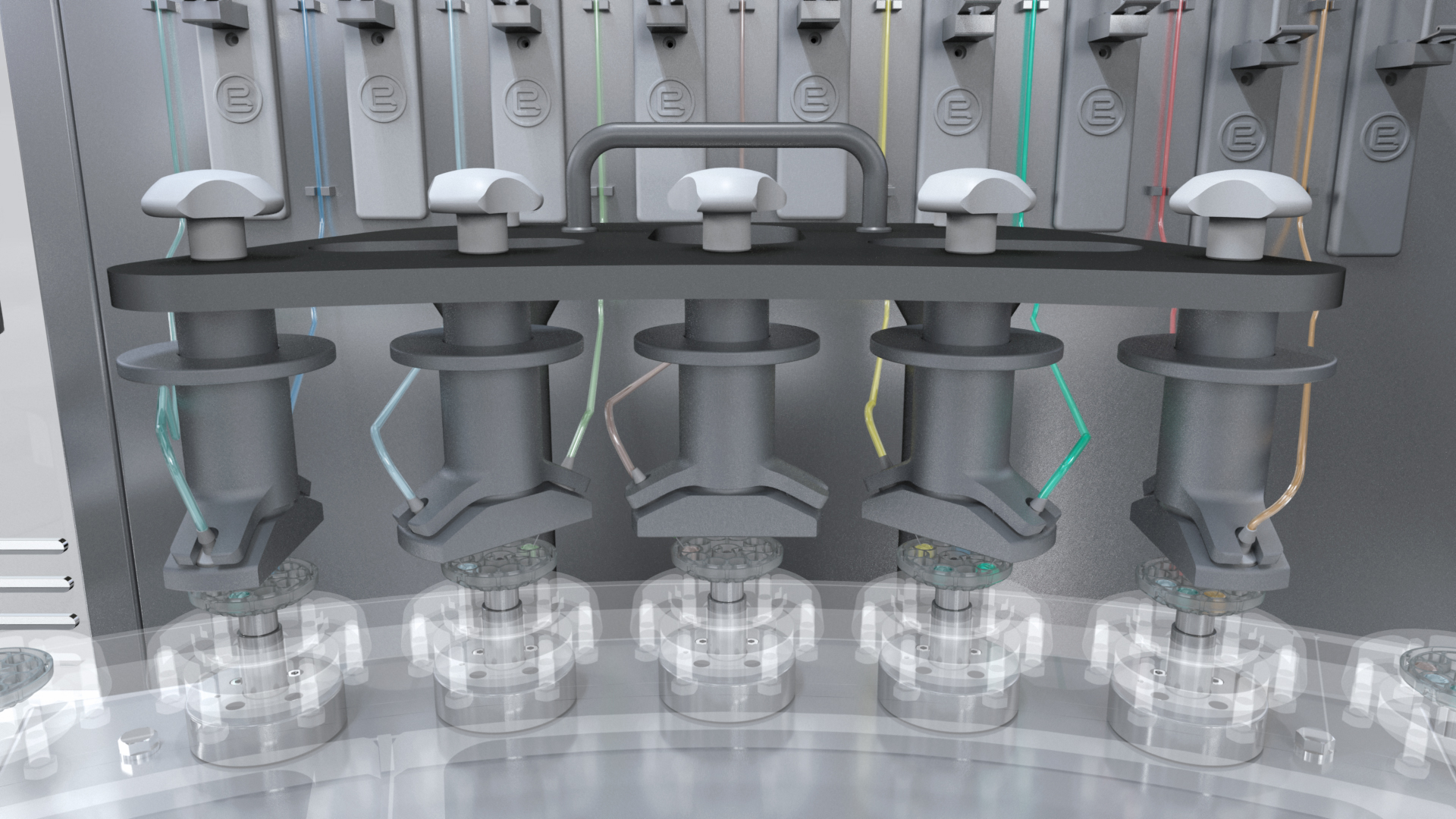

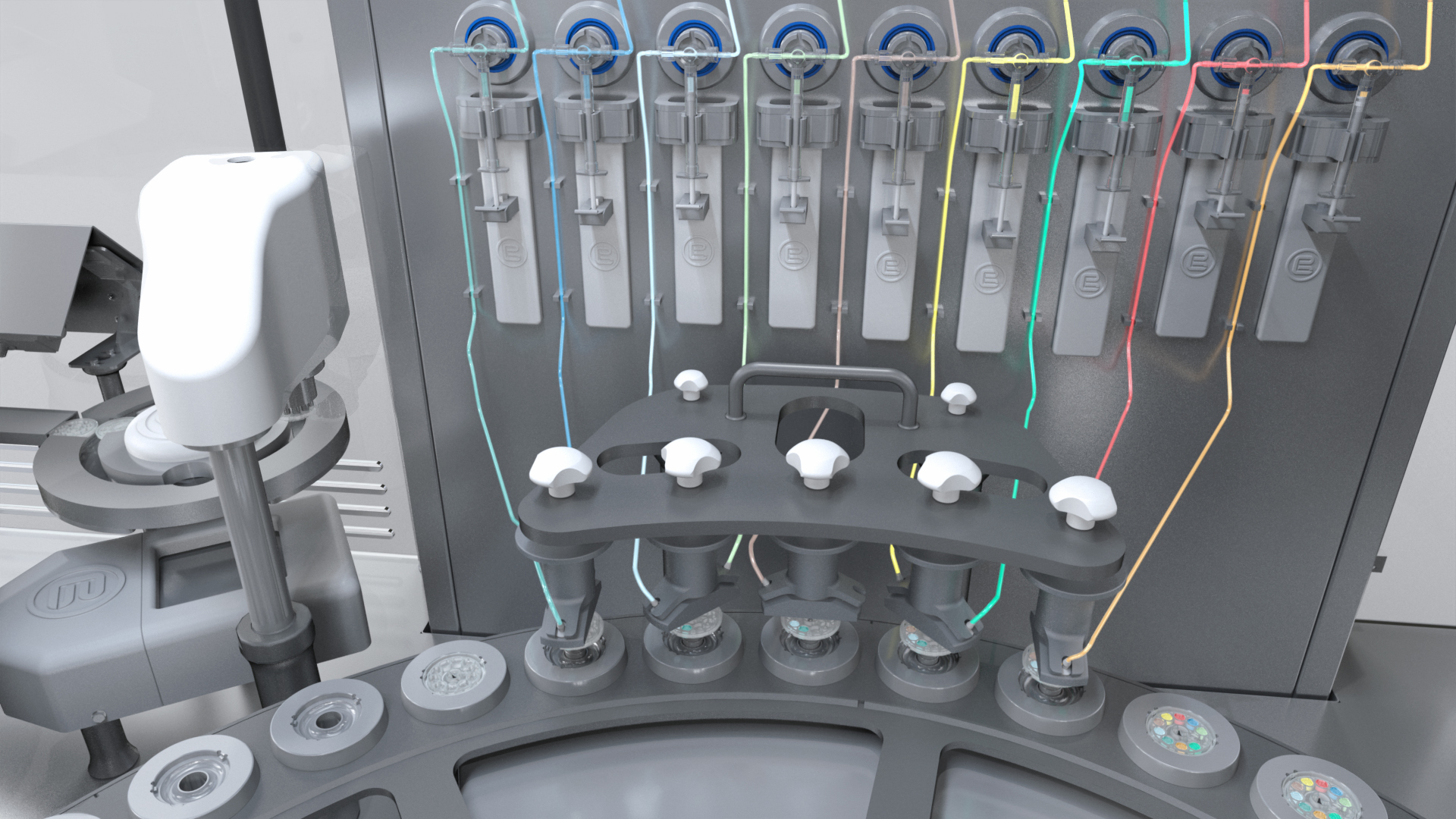

⦁ Customized MICRO-DOSING dispensing unit

⦁ IPC (100% In-Process Control) with retroactive feedback to the dosing system

More features

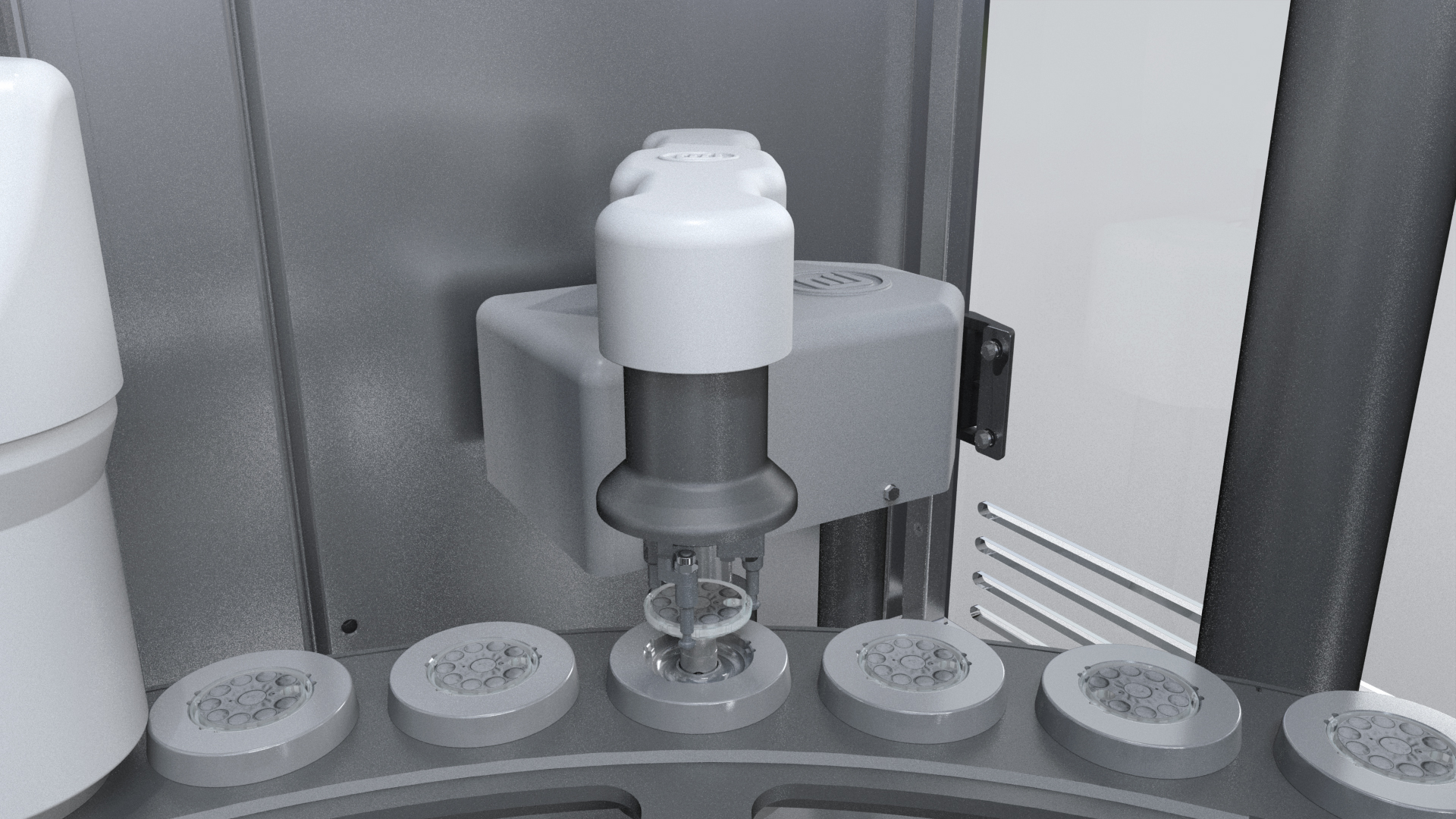

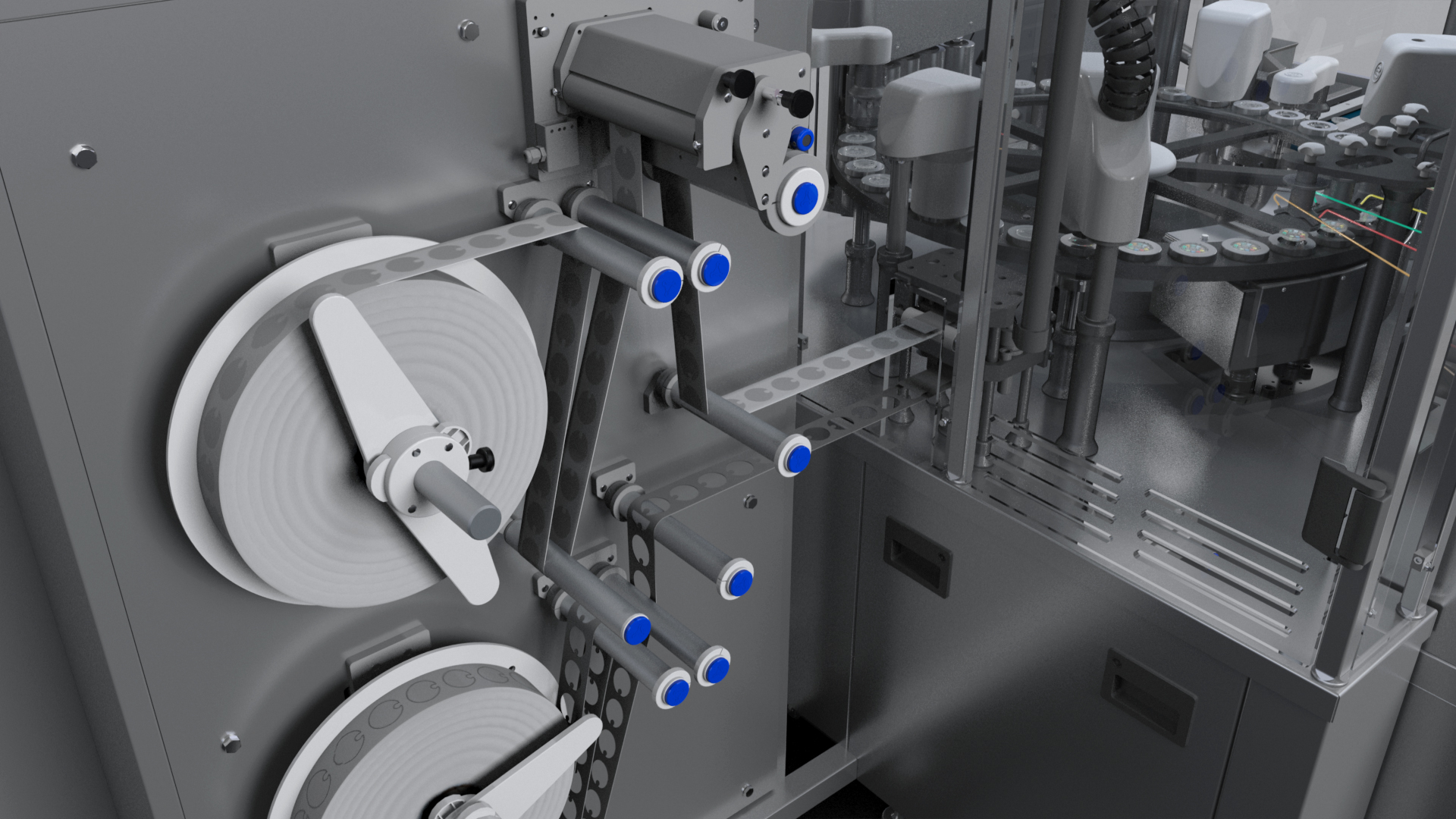

⦁ Cut & welding unit

⦁ Camera welding control

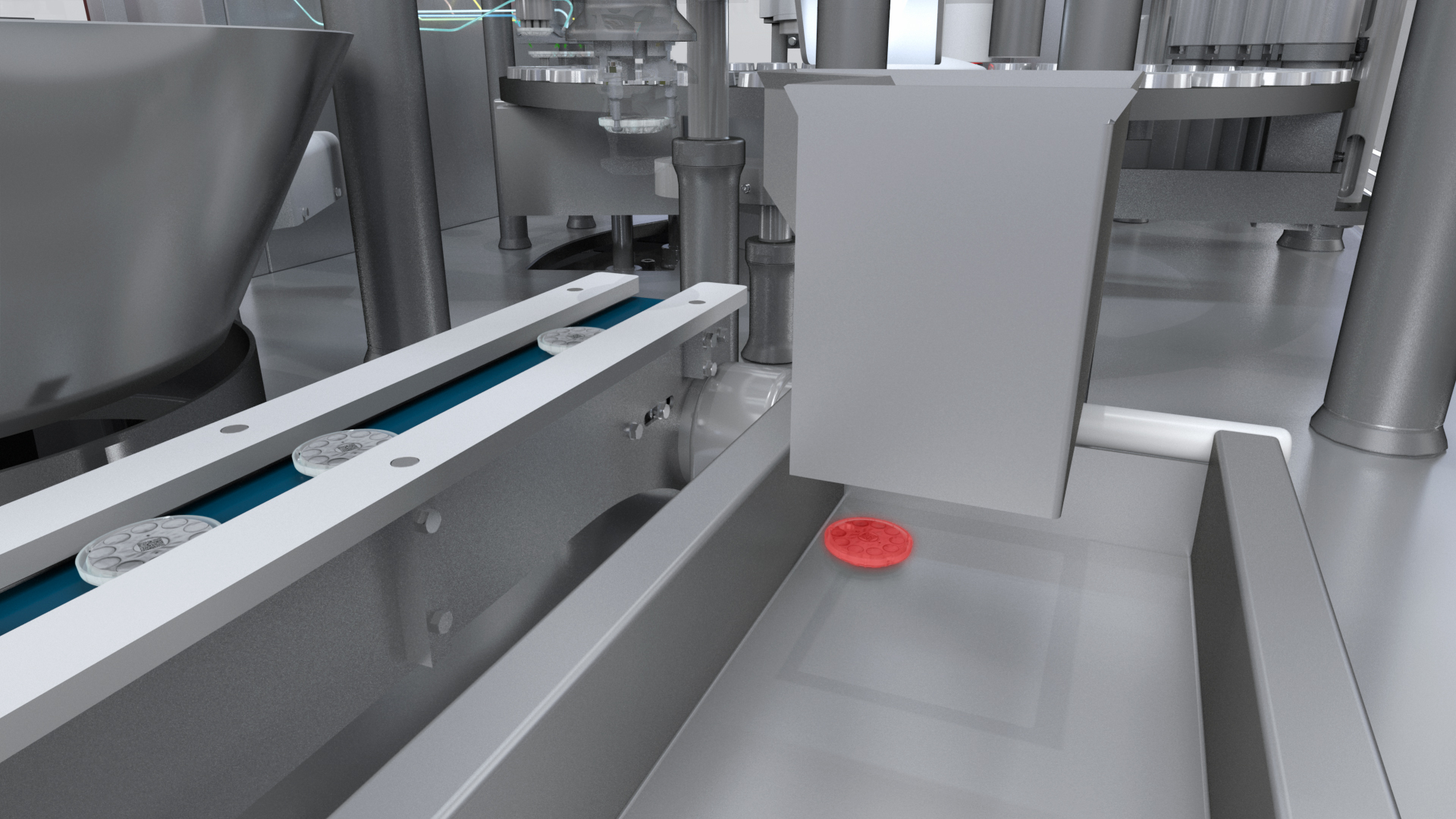

⦁ Leak test (vacuum decay) control

⦁ Ink-Jet for MATRIX code printing

⦁ User-friendly and fast tool-free format change

⦁ Filling range: from 20 µL to 200 µL

Machine Output

20 to 400 BpM

Compatible containers

Contact us