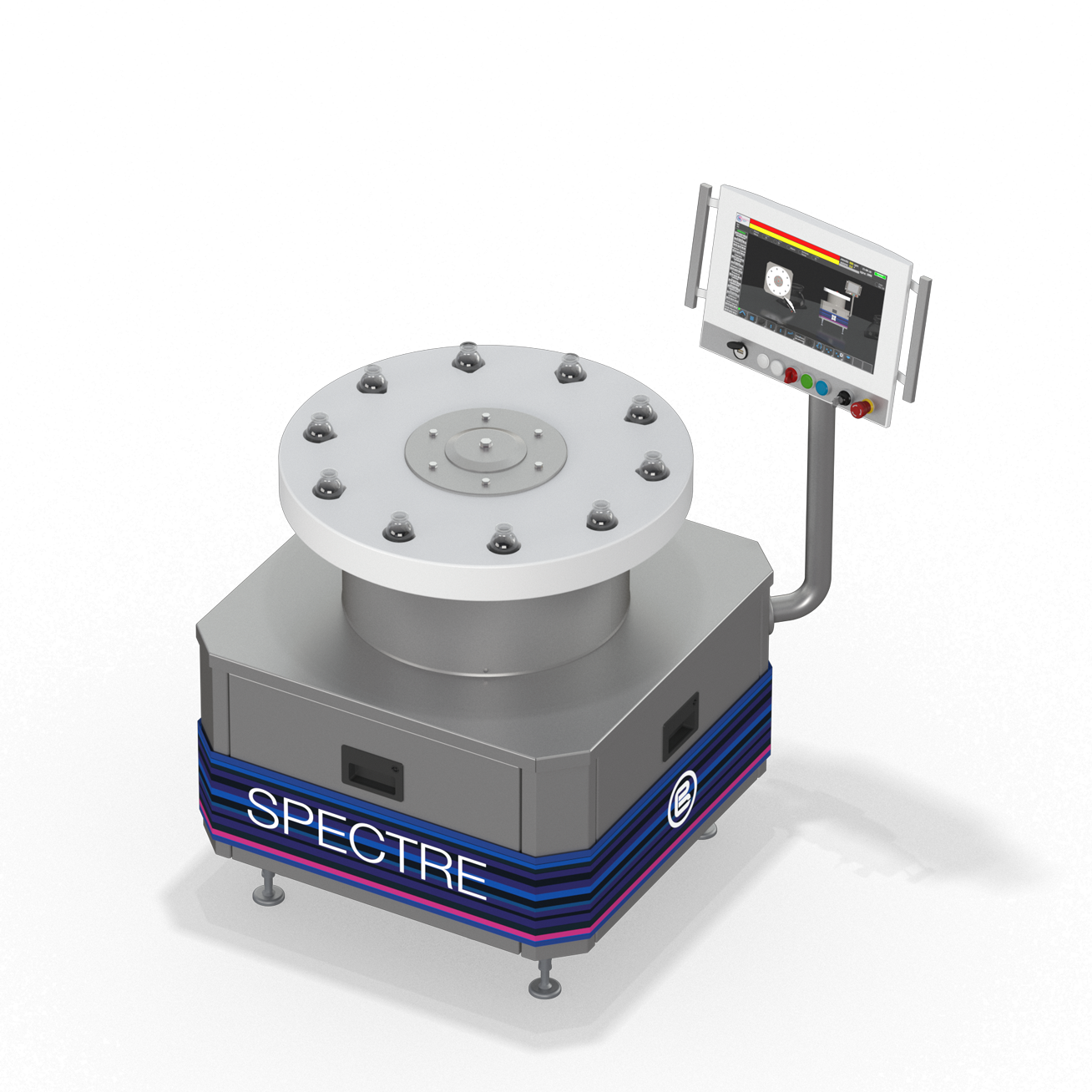

Overview

According to the packaging and product, PBL can exploit various spectroscopic technologies (such as IR, UV-VIS, RAMAN), combined with a neural network that uses deep learning (AI) technology to perform a non-invasive chemical inspection and determine the conformity of the individual pharmaceutical product, in terms of concentration of active ingredients and impurities.

Main features

• Non-invasive chemical analysis for the conformity of finished pharmaceutical products.

• The system is now able to distinguish between different concentrations of APIs and impurities of the solution with > 95% accuracy

• Patent pending

• Spectroscopic analysis: real time data collection

More features

• Deep Learning (AI) technology: real time data processing

• IN-LINE, NON-INVASIVE analysis: no need for sampling, no product waste

• Time of analysis: less than 1 second for bottle

• Suitable for different formats and product types

• Safer and cheaper pharma production

• Waste is greatly reduced

Machine Output

15 to 300 BpM

Compatible containers

Artificial Intelligence Technology

Thanks to our proprietary AI-technology we are able to offer the unmatched ability to recognize, in real time, the presence of particle defects and leaks in both rigids and flexible containers.

Project funded:

Contact us